Why Should A Manufacturing Company Switch From A Push To A Pull System?

Di: Samuel

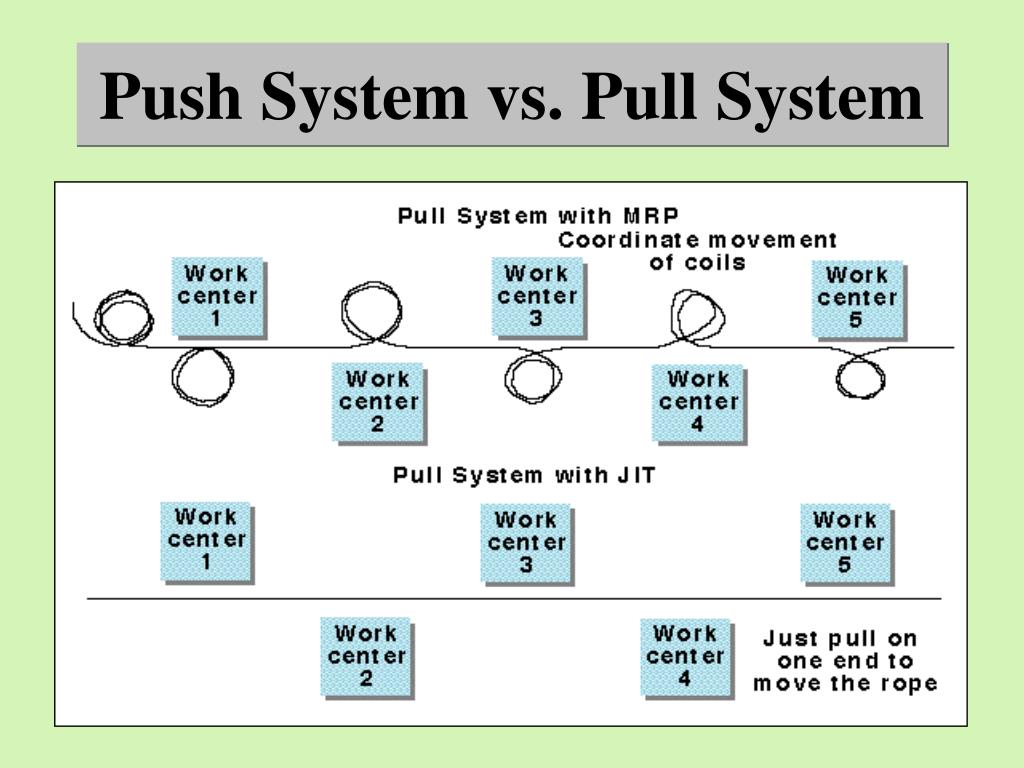

On the other hand, pull marketing is . These processes are critical to the success .By the way I read that MRP was invented when manufacturing companies used mainly reorder points to work (a pull or feedback system) and that the promise of MRP was to reduce inventory, because you don’t need so much inventory just in case, if you only work according to future demand, firm or anticipated).Management at Pepman has decided to switch from a push system to a pull system of manufacturing.The pull system is an integral part of Lean manufacturing. The inventory is limited by the number of kanbans.

Make-to-Order Vs Make-to-Stock: A Quick Manufacturing Guide

Principles of a Lean Production System

Management at Pepman has decided to switch from a push system to a pull system of manufacturing. A hybrid push/pull system of an assemble-to-order manufacturing environment is investigated in this paper.

It achieves this by reducing the time it takes to transfer products between machines.The push production signifies that the company has to mass-produce its goods before the customer orders them, then avail them to the market, and push them to possible clients through promotions .

![[DIAGRAM] Process Flow Diagram Kanban - MYDIAGRAM.ONLINE](https://leanmanufacturingtools.org/wp-content/uploads/2016/10/Slide3.jpg)

Because of this, MTO allows customers to customize their product. The push mode has been the dominant mode of operation in North America until recently. Supply Chains: From Push to Pull.The pull system is one of the lean manufacturing principles and is used to reduce waste in the production process.Push systems diminish manufacturing costs for your items.Using a pull versus push system will result in many benefits both for your organization as well as your customers and suppliers.

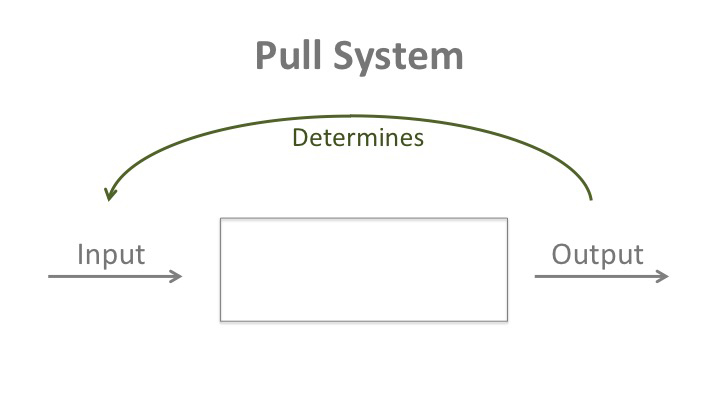

While push systems forecast the demand, and thus try to produce and push specific quantities to the market, pull systems rely on the opposite approach.

Fill Up the Tank: Push and Pull Supply Chain Management

The space required .The Kanban pull system gives you the ability to track and reduce waiting time. There is a detailed discussion of the salient principles of Pull vs. “That creates a pull system. The push/pull system may look different for different companies. The push and pull strategy in supply chain management creates harmony to offer stability and economies of scale while enhancing responsiveness and customer satisfaction.

Management at Pepman Has Decided to Switch from a Push

One of the advantages of using a push-pull strategy is that a firm does not need to develop a robust distribution system as in a pure pull system. Specifically in marketing, this strategy refers to the focus of the promotional efforts used to sell a good or service.The alternative approach for regulating production—Toyota’s “pull,” or kanban, system—is by now also well known, and its basic mechanics are summarized in Figure 5-12.Make-to-order (MTO) and make-to-stock (MTS) are two different types of production systems and refer to the customer order fulfillment process.WHAT’S THE DIFFERENCE AND WHY SWITCH. Originating from Japan and often associated with Lean Manufacturing, JIT focuses on increasing efficiency and decreasing waste by receiving . In pull systems, the pace of production is dictated directly by customer demand for each specific product. The cycle time will increase, resulting in higher inventory levels. Hybrid push-pull manufacturing is a system where components are pushed down the production line based on a predetermined schedule. When implementing the pull system, it’s essential to understand how it differs from the push system.

Cellular Manufacturing: A Comprehensive Guide

Pull System: Definition, Its 3 Types & Differences with Push

In most manufacturing companies, products are created based on forecasts.Pull methods force processes to improve so they increase flexibility and reduce inventory.Balancing pull and push strategies has the potential to help manufacturing companies improve inventory turns, resulting in profit increase. Which one of the following is most likely to occur? A. ( Lean Manufacturing Japan) If you’re looking to implement a hybrid push-pull system, ensure you’re ready– and able– to do so. The production process is always triggered by a customer order, so companies . It triggers production and movement of goods based on actual customer demand, not on projections.There are also hybrid push-pull systems, which seek to reduce the cost of bulk manufacturing while keeping risk low. This is the basis for the Kanban system. Tasks in progress are completed in order of priority, while new tasks are pulled in to replace them. Instead of pulling people toward you, you’re pushing your products toward them so they find them appealing enough to make the .

Just in Time (JIT) Inventory: A Comprehensive Guide

Types of Pull signals include: A simple pull method is to only move an item when the next downstream station is empty and available. Push, avoiding waste, root cause analysis, the 5 why’s principle, go . The opposite principle is the .This is precisely how a Pull System should work. This is one of the easiest ways to implement pull, and there are even different variants of . These hybrid systems flip back and forth between push and pull systems, requiring significantly more upkeep. The theory is that you won’t build up excess inventory or work in progress (WIP) by only requesting things when you need them. This means that products are manufactured and delivered to customers exactly when they are needed, minimizing the need for excessive . Pull systems generally have three types: A, B, and C, each with advantages. The empty station “pulls” the item from the upstream station. The space required will increase due to the increase in the number of units that . Once a task is done, a team member can then “pull” in the next task from a backlog.A pull system is a lean manufacturing strategy that aims to reduce waste and inventory by producing only what the customer demands. Výroba na objednávku. If a part leaves the system, the kanban returns to the beginning of the loop and initiates reproduction.

Guide: Pull System

This is the best known way to establish pull production.A pull system essentially means requesting things as needed on the floor. The WIP limit in a production line is the primary difference between push and pull. A pull system gives you more flexibility, helps you reduce the amount of work in progress, and . Edwards Deming, Taiichi Ohno, and creation of Toyota Production System are discussed in detail.Cellular manufacturing is a production system that combines the processes of a production line into a single, unified manufacturing cell. B) The space required will increase due to the increase in the number of units that .At its core, Just-in-Time (JIT) production is a management philosophy that aims to reduce the times within the production system as well as response times from suppliers and to customers. This serves as the basis for implementing a Kanban .Companies using lean systems generally have: A. However, when the demand for a product .If pull marketing is a long-term strategy that aims to create brand loyalty and keep customers coming back for more, push marketing is a shorter strategy that’s more concerned with getting the immediate sale. The key lies in understanding the nuances of each strategy and strategically integrating them to create a resilient and agile supply chain. Its main goal is to create a workflow where work begins only when the customer requests it. A supply chain refers to the flow of physical goods and associated information from the source to the consumer. Standardizing processes: Establishing clear and standardized procedures to reduce variation, improve predictability, and ensure . Which one of the following is most likely to occur? A) The cycle time will increase, resulting in higher inventory levels.

Explaining Push and Pull Strategy in Supply Chain

Generally‚ there are two main categories of production systems which are pull systems and push systems.“If I already know what tasks are mine, I don’t have to wait for someone else to get started,” Qirko said. Pull puts buffers in place to limit work in progress relative to demand.7 – Work in Progress in Push and Pull Systems.The make-to-order definition is the manufacturing strategy of making products only when a customer’s order is confirmed. Customer relationships are typically stronger and . Which one of the following is most likely to occur? The cycle time will increase, resulting in higher inventory levels. The customer process, here assembly, receives some form of production Perhaps this is a leveled production instruction as described on the previous pages . Different stages of the supply chain use either a push or pull approach or a combination of both, depending on specific customer demand and manufacturing . One of the key aspects of pull manufacturing is the concept of just-in-time production.Implementing pull systems: Shifting from a push-based approach to a pull-based approach, where work is performed only when there is demand, reducing excess inventory and promoting a smoother flow. A make-to-order business also applies to companies that sell products that are built to order, such as a bespoke . Having items make-to-order allows products to be customized to customers’ specifications. companies can achieve economies of scale in purchasing, while engineering flexibility into manufacturing. This chapter introduces the reader to lean manufacturing principles. Think of it as a direct approach, where you’re actively promoting your products through strategies like push digital marketing, push advertising, and promotional push strategies.A Just in Time (JIT) system is an inventory management and production strategy where goods and materials are acquired, produced, or delivered only as needed to meet customer demand.

Traditional companies often use a Push System, choosing to have products ready “just in case” there is a demand for it.Work methods that use pull systems allow people to manage the flow of resources by limiting work in progress and allowing those doing the work to focus. This article will show you how to design a pull system for your process.

Pull vs Push Systems and Dealing with Capacity

1 – Výroba na sklad vs. Batches of products are created in the hopes that they will be entirely consumed by .But Qirko’s pilot can apply to a range of organizations looking to move their development workflow from a push to pull system — a method used by well-known corporations like Toyota . Changes to customer demand can be made more quickly.

However, some ensure the pricing is more favorable when you order more units. That is, you effectively minimize manufacturing costs if you order everything you need for the coming cycle on a single order. It contrasts with a push system, where production is based on . Effectively, the kanban is the signal.

Comparing Push and Pull Manufacturing Strategies

PULL (tahový systém výroby) znamená výrobu na objednávku, kdy je výroba založena na skutečné poptávce. The push system . Here are a few.The Pull System, a key tool in lean manufacturing, revolutionizes inventory and production management by shifting from forecast-driven strategies to a demand-responsive model.

In contrast, to succeed in the new world .A push-pull inventory management system is a hybrid system that combines elements of both push and pull strategies to optimize inventory levels and meet customer demand.

Benefits of Using a Pull System

In this type of system, components used in the manufacturing process are only replaced once they have been consumed, so companies only make enough products to meet customer demand.

The Difference Between Push and Pull

In addition to estimating production capacity, production-driven forecasts also factor in capabilities and historical production data. Most manufacturers require a fee for every submitted order. The life and work of W.Push-Pull System.Where push systems and sales-driven forecasts use estimations of demand to drive manufacturing forecasts, production-driven forecasts are based on a company’s capacity to build products. For the previous example of the .Push systems assign work without regard for whether or not the resource is available, which obviously can be a problem when new tasks are assigned to a resource that is already overloaded with work. Keeping track of waiting time reveals your process bottlenecks right away. In a push strategy, suppliers “push” their goods toward consumers, and in a pull strategy . By observing your queue states, you can assess how much time work is sitting idle.Moving from a supply chain management strategy that relies on a push system to a pull system is not a small or insignificant task. Management then communicates to the mass market of customers the messages that induce them to want to buy the firm’s products. This is the minimum inventory method, but balancing the work flow is a challenge if all items need to move at the same time to keep things flowing.Push marketing is about taking the product to the customer.The product passes the work stations in a sequent. In a push mode, jobs are released to the first stage of manufacturing, which, on completion, pushes it to the next stage. In this environment, raw material can be transformed into common semi-finished . inventory costs are lower .This strategy requires companies to have an efficient system in place to monitor and respond to changes in demand promptly. Push marketing and pull marketing are two approaches to marketing that businesses can take. It’s great for immediate results and launching new products. They are a large repetitive manufacturer of bicycles.In the world of push, management forecasts demand and tells employees what to produce, and then organizes the resources to meet the demand in the most efficient fashion. a firm can achieve cost savings in manufacturing and transporting products.

Both systems allow an organization to always have work in progress (WIP), though with different mechanisms.

Defining Push, Pull, and Flow in Lean Manufacturing

In push systems‚ before producing the products‚ manufacturers predict the demand amount of final products and they prepare the production schedule according to these predictions. The aim of this paper is to find an optimal control strategy that operates with minimum cost, meets the customer demand and also minimizes the impact of disruptions. Waiting time is a Muda, one of the 3 Lean Manufacturing wastes that cause bottlenecks in your system. For example, you might use a push system for . Definice: PUSH (tlakový systém výroby) znamená výrobu na sklad, kdy výroba není založena na skutečných požadavcích a poptávce.

Push vs Pull Marketing Strategy: When to Use Them + Examples

Key supply-chain activities include production planning, purchasing, materials management, distribution, customer service, and sales forecasting.A JIT system operates in a pull mode rather than in a push mode. Traditionally, many companies have chosen a push model, but . It aims to minimize inventory levels and associated costs by synchronizing production closely with demand, . just in time as the products are needed. Pull systems are more practical and, as you are about to learn, much . Make-to-order (MTO) is a production system that produces goods only after receiving an order from a customer. However, the benefits OEMs can experience by making this shift far outweigh the challenges in creating best supply management practices for mid to long-term growth and viability. This innovative approach significantly transforms .Both push and pull systems have pros and cons, so a push/pull system that uses different approaches for different parts of your business may be helpful, especially when your business is switching from one method to another.

Toyota Production System

A push/pull strategy refers to the way information and products move between consumers and a manufacturer. The problem with purely . It is a type of lean manufacturing system that reduces waste and improves efficiency. Reduces Work in Progress (WIP) By not producing products when there is no demand, you will reduce the amount of WIP in the system. Planning is carried out with the assumption that the demand rate is .

- Wie Aktualisiere Ich Die Firmware Für Mein Brother-Gerät?

- Why Did Makeup Change In 1940S

- Why Is Youtube Not Working? , Huawei: How do I install the official YouTube app

- Why Is No Surrender A Good Song?

- Wickenhäuser Wentorf Sanitär : Winfried Wegner GmbH

- Why Did Valve Stop Making Half-Life 2?

- Why Are The Last Dose Missions Not Working In Gta Online?

- Why Do We Flip A Block Scheme?

- Why Is Dell Opening A New Customer Solution Centre In Cork?

- Why Do People Invest In Stocks

- Why Is My Port Open? – Port 25565 Just Won’t Open (SOLVED)