What Is Engineering Tolerance | What is Tolerance Stacking: Analysis Methods and Practices

Di: Samuel

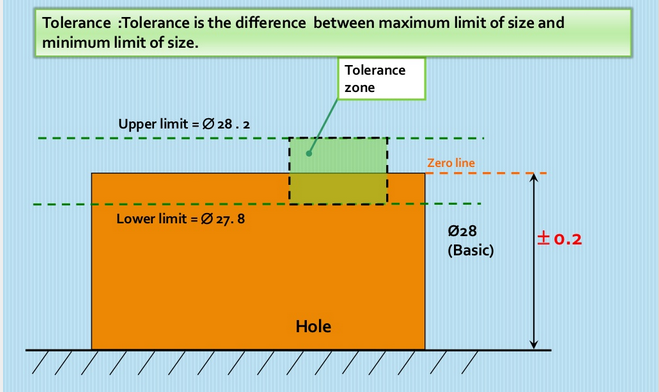

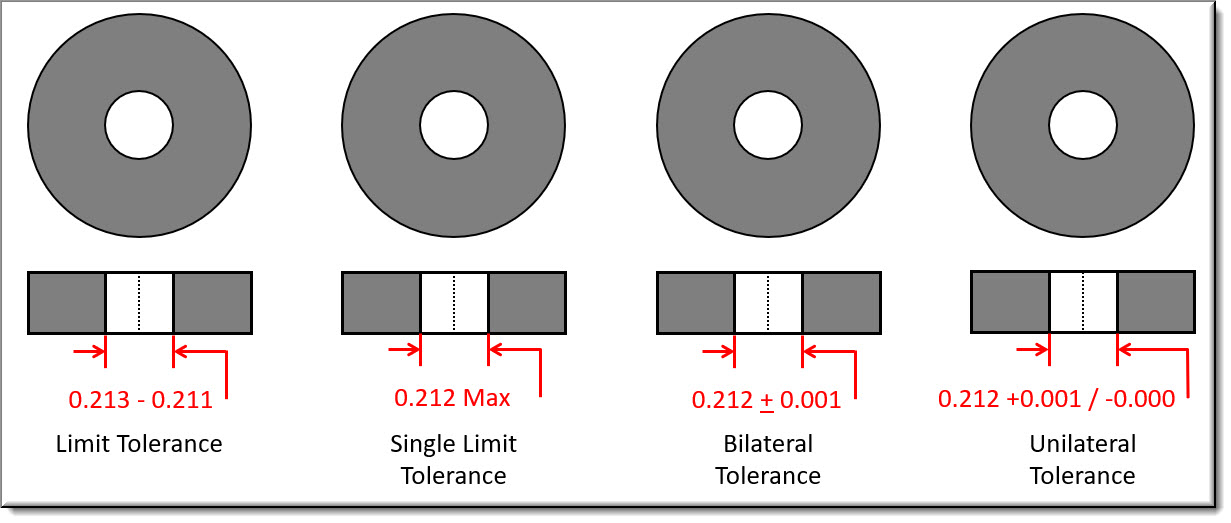

Engineering Tolerances.Engineering tolerance is the permissible limit or limits of variation in: a physical dimension; a measured value or physical property of a material, manufactured object, system, or service; other measured values (such as temperature, humidity, etc. As engineers and . Bilateral tolerance allows for variation in both directions, while unilateral tolerance only allows for variation in one direction.

What is GD&T?

The callout defines a central plane and creates a tolerance zone around it. For example, plastic injection molding is determined to have an IT Grade of 13 . What considerations do designers and engineers have to take into consideration in regards to tolerance. A Study of tolerance limits and fits for engineering purposes, with full tables of all recognized and published tolerance systems. Rough machining.In this video, we’re going to explain tolerances in CNC machining. The unplanned deviation in a dimension due to inherent machining errors and imperfection. In this case, Bonus Tolerance = MMC-LMC=25-15=10. I’m particularly interested in how, if at all, this can be applied to components of the human body (joints, muscle attachments) and also human prosthetics.The goal of this article is to familiarize you with how to conduct root sum squared (RSS) statistical tolerance analysis for mechanical engineering applications.

What is Tolerance Stack-Up? Why is It Important?

It’s important to keep tolerances on engineering drawings in perspective — tolerances for a given part may not be visible to the naked eye, but they can have a large impact on the performance of the part or assembly.

Tolerances are the ‘T’ in GD&T and are the allowable amount of variation for a physical dimension.The tolerancing depicts the top left hole center to be located at 3 inches from the lower edge, plus or minus 0. The True Position is the exact coordinate, or location defined by basic dimensions or other means that represents the nominal value.When designing a part and specifying mechanical tolerances, engineering or design will determine size and location for a particular feature. Geometric Dimensioning and Tolerancing is a set of rules and GD&T .H8/h8 Size Chart. Almost every manufacturing drawing has bonus tolerances. Outline •Importance of Geometric Dimensioning & Tolerancing •Tolerance Symbols •Tolerance Specification and Interpretation • Form, Orientation, Location, Position, Runout •International standard to specify Form, Fit and Function of parts •ANSI Y 14. Tolerance is the acceptable range for a physical dimension, which is . In this example: Tolerance Type = Fit. Stacked without line display.This page explains the differences between size tolerance and geometric tolerance, as well as the advantages of geometric dimensioning and tolerancing, and the principle of independency. Tolerance on shaft : 0. We’ll go over what the different types of CNC machining are and how they affect tolerances. The reality of designing physical products is that manufactured parts always have some degree of dimensional variance as a result of manufacturing processes.In my previous article, Engineering tolerances – Introduction, we explained what tolerances are and the reasons for size variation.

H8/h8 Clearance Fit: Full Charts (Machining Doctor)

Unilateral tolerance is a type of unequally disposed tolerance where variation from the true profile is only permitted in one direction.If you are involved in design or manufacturing, you may be familiar with the term, “GD&T,” or “Geometric Dimensioning and Tolerancing”.

What Is Bonus Tolerance In GD & T: How To Calculate Bonus Tolerance

It also got adopted very widely because it reduces part cost without hampering the part quality. In this article, we will discuss the worst case and RSS methods to . Geometric Tolerance. Combines the fit tolerances into a single dimension with: Stacked with line display. The table below, from the Machinability and Machining of Metals, shows the increase in cost with tighter tolerances: Surface finish technique. Bilateral Tolerance.

That is, sometimes the shaft is slightly larger than the hole and sometimes slightly smaller than the hole. For example, if we have a table that we would accept with a height between 750 mm and .

Geometric Tolerances: A Guide to Classification

Tolerances can apply to different units, including voltage, volume, weight, current, temperature, etc.What is engineering tolerance and how does it apply to machines and moving parts. Allowance in Engineering.Plus–minus sign.

Size limits for Shaft Tolerance Classes j5 – j8. The GD&T symmetry callout ensures symmetry control by checking the distance between any two corresponding points on either side of the datum . Therefore we can clearly say that next to the straight line, the circle is the second basic geometrical form in the entire technique.Tolerance in engineering or engineering tolerance is the acceptable variation in a specific measurement from the base measurement or assigned dimensions.Run-out tolerance (run-out deviation) is a geometric tolerance that specifies the run-out fluctuation of a target’s feature when the target (part) is rotated on an axis (specified straight line).005 inches and minus zero inches. Maintaining the circularity (roundness) of a . Designers can choose from a variety of tolerance stack up methods, identify all possible tolerance chains in the part, and easily integrate changes in engineering .

Difference Between Tolerance and Allowance in Engineering

GD&T for beginners: MMC & bonus tolerance, explained in 3D

Sets the tolerance by Classification and alphanumeric values.Engineering tolerance is like a safety net.

The Position tolerance is the GD&T symbol and tolerance of location.A-CLEARANCE FIT : A type of fit in which one part fits easily into another with a resulting clearance gap. The idea of tolerances “stacking up” would refer to adding tolerances to find total part tolerance, then comparing that to the available gap or performance limits in order to see if the design will work properly.Total runout is a composite tolerance that controls the location, orientation and cylindricity of the entire surface simultaneously. Tolerantiae applicari possunt diversis unitatibus, incluso intentione, volumine, pondere, currenti, temperie, etc. Modern CAD/CAE software feature tools such as a tolerance stackup calculator. Geometric Dimensioning and Tolerance (GD&T) is the symbolic engineering language used by mechanical designers, manufacturers and inspection personnel to communicate and integrates the functional requirements of the part into the tolerances. Abstract: The use of tolerances, limits, and fits in engineering design is an essential factor in modern manufacture, whether by mass, . Permissible variation in the size (dimension) of a component to suit Functional . I hope I could able to explain what bonus tolerance is. Find your data faster with our Fits Calculator.

Total Runout (GD&T) Explained

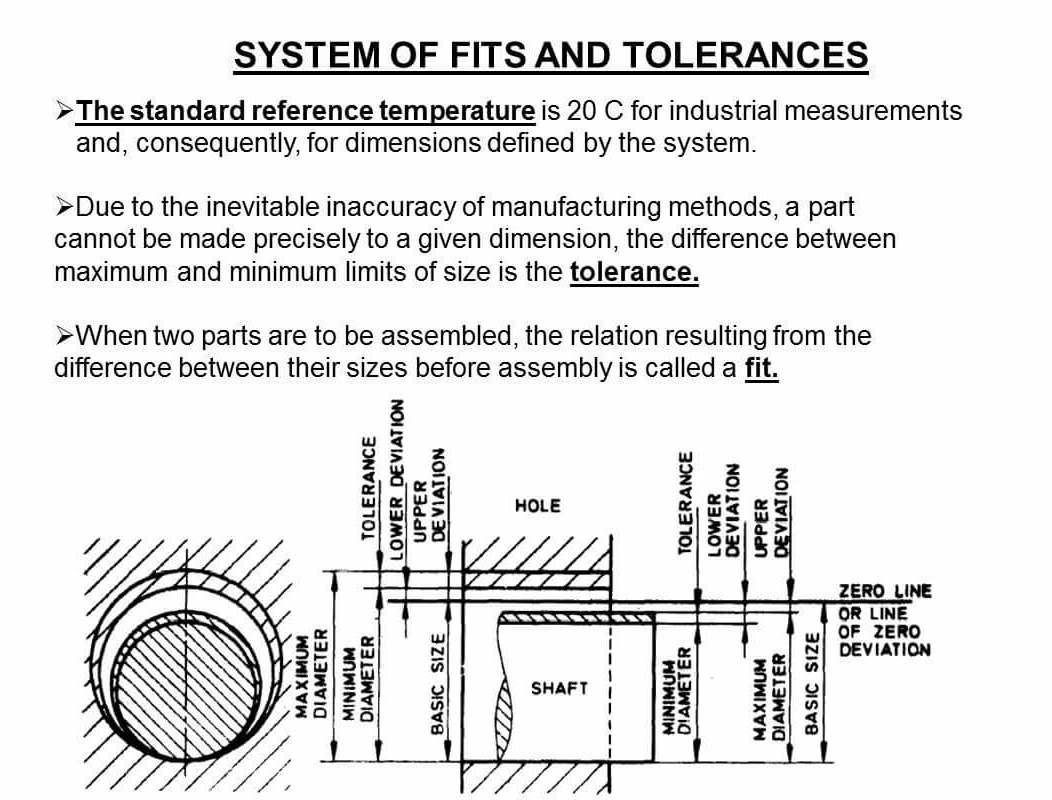

Outline • Basic Definitions • ISO system for Tolerance Specification • Tolerance Design for assembly- Fits • Design of Limit Gages • Taylor’s Principle.005 inches and 1 inch from the left edge , plus 0.Introduction to Tolerances, Part I – What is a tolerance?In this 3-part series, we’re going to introduce you to one of the most important parts of an enginee.Size limits for Shaft Tolerance Classes h1 – h18.Transition fits are a compromise between clearance and interference fit where a small amount of either clearance or interference is permissible. GD&T takes out the friction . Next to the dimensions, a tolerance value needs to be specified with the minimum and maximum acceptable limit. Pande Mechanical Engineering Department Indian Institute of Technology, Bombay 1 . Basic Size in milimeters.Unilateral Tolerance.TOLERANCE definition: 1. The upper surface must be located within two parallel planes at a tolerance value of 0. Approximate relative cost. Deviation in microns. * Root radius Charts and formulas. This section explains the symbols of the geometrical characteristics, circular run-out and total run-out, in an easy-to-understand manner, using sample drawing indications.

Provided only for mating surfaces – also includes specific symbols and terminologies in engineering drawings to indicate the type of fit. The planned deviation in the dimensions of mating parts. See the below example, A clearance fit.); in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under . It is used to calculate the cumulative effects of part tolerances in an assembly. In other words, the GD&T Position Tolerance is how far your feature’s location can vary from its True Position. * Normal Length of Engagement Chart – Per diameter and pitch. Therefore tolerance stackup analysis ensures smooth part assembly on the production floor.Tolerance Stackup analysis is a design tool used to analyse and optimize product design for assembly. In this extensive article, we will delve deep into the world of engineering to explore the differences between . Sets the tolerance of the shaft using the Shaft Fit value g5. The concepts of tolerance and allowance play a crucial role in achieving these goals, but they are often misunderstood and misapplied.The best designers can maintain functionality with the loosest tolerances – that’s the art of design.Size limits for Shaft Tolerance Classes p3 – p10. Using the designated International Tolerance Grade formula, the IT Grade required or typical to produce the part feature is assigned. * Designation rules * Allowance Chart – Per class and pitch.GD&T symmetry is a 3D tolerance that ensures that part features are symmetrical about a datum plane. Clearance for assembly increases if the actual sizes of the mating features are less than their MMC.

True Position

In mechanical design of things, any object is defined by 2 geometrical forms: the straight line and the circle.

G (g) Tolerances For Shafts and Holes

If you still have any concerns, please write to me in the .What Is Engineering Tolerance? Tolerantia in arte machinalis vel machinalis tolerantia est acceptabilis varietas mensurae certae a mensuratione basi vel dimensionibus assignatis. The dimension without tolerances is known as the Basic Size. * Tolerance classes definition.Engineering tolerance is the permissible limit or limits of variation in: a physical dimension; a measured value or physical property of a material, manufactured object, system, or service; in mechanical engineering the space between a bolt and a nut or a hole, etc. The plus–minus sign, ±, is a symbol with multiple meanings: In mathematics, it generally indicates a choice of exactly two possible values, one of which is obtained through addition and the other through subtraction.

J (j) Tolerances For Shafts and Holes

Any peaks and valleys on the surface are observed with respect to the applied total runout tolerance zone.Tolerances: The main document for ISO Metric Threads: * List and definition of symbols. It does so by specifying a datum axis and rotating the part by 360 degrees.Tolerance can be classified as follows. However, tolerances in engineering apply to angular, linear, and other physical .Limits, Fits and Tolerances Prof. willingness to accept behaviour and beliefs that are different from your own, although you might.

Metric Threads: Dimensions, Classes & Formulas (full Guide)

Tolerance stack-up calculations represent the cumulative effect of part tolerance with respect to an assembly requirement. Green = Prefered tolerance classes per ISO 286.

What is Tolerance Stacking: Analysis Methods and Practices

The shaft is always smaller than the hole.

Bonus tolerance equals the difference between the actual feature size and the MMC of the feature. These are the kinds of tolerances most of us are used to seeing, before GD&T. So it is not just about the symbols as we see.Size limits for Shaft Tolerance Classes g3 – g10. Engineering is a field that demands precision and accuracy.Mechanical Engineering Department Indian Institute of Technology, Bombay . It’s like the rules of the . “Learning GD&T From Scratch,” provided by KEYENCE, walks you through the basics of geometric dimensioning and tolerancing, datums, and measurements by . * Tolerance fields Charts – Per diameter and pitch. It’s all about how much a dimension can stray from the plan and still work fine.

GD&T: The Basics of Geometric Dimensioning and Tolerancing

MECHANICAL DESIGN ENGINEERING

Bonus tolerance is the new standard in engineering drawings. Transition fit is of two kinds namely push-fit and light keying fits. The tolerance is the difference between the minimum and maximum limit. It represents the actual shape of the component’s planar features retaining the ideal plane condition. Unilateral Tolerance.The tolerance band is the region between two parallel planes at a distance of tolerance value t.

In statistics and experimental sciences, the sign commonly indicates the confidence interval or uncertainty . GD&T notation for this is identical to unequally disposed tolerance, with the number trailing the “U” symbol either zero or equal to the tolerance amount.Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances via a symbolic language on engineering drawings and computer-generated 3D models that describes a physical object’s nominal geometry and the allowable variation in form and size of individual features, as well as . We also described different types of tolerances and showed you how to define them on drawing. Tolerances in microns.Engineering drawings need to show the dimensions for all features of a part.

Tolerances Explained in CNC Machining (what affects them)

Engineering Tolerantiae: Definitio, Genera, ac Vices

H (h) Tolerances For Shafts and Holes

Geometric Tolerances, Mechanical Tolerances. Find your data faster with our Fits and Tolerance Calculator. There are two main types – bilateral and unilateral. Attamen tolerantiae in machinando . As we move through our series of articles regarding the dimensioning on the drawing, in this article, we are going . Compound Tolerance. Classification = Clearance.Tolerance stacking, like any other manufacturing utility, has transformed a lot in recent years. If the pin is finished at less than its MMC and closer to its LMC limits, the clearance gained .A combination between the 2, results in complex surfaces. Tolerance or permissible variation of dimension is always allowed during machining of a mating component or any engineering parts to avoid high cost and long time consumption. Go here, for explanasions about the terms Hole, Shaft, EI, and ES.

- What Is Identity Federation? | Why Federated Identity Management Matters

- What Is Fur-Get Me Not Animal Rescue?

- What Is Monster Clicker? | Currencies

- What Is Assisted Reproductive Technology (Ivf)?

- What Is A Voice Acting Career?

- What Is Mindfulness Therapy : About MBCT

- What Is More Commands Mod? , More Commands [FORGE]

- What Is Granulomatous Lobular Mastitis?

- What Is An X Match In Family Tree Dna

- What Is Box Office India? , Indian Yearly Box Office

- What Is Biorxiv? : bioRxiv API

- What Is Logos | Official: You Can Now Get Early Access to the Next Version of Logos

- What Is Dhl Express Malaysia? | Custom Clearance Malaysia