What Are Plastics Properties? , Acrylonitrile Butadiene Styrene (ABS Plastic): Uses, Properties

Di: Samuel

It is a high-modulus . Phenol and formaldehyde, often known as phenol-formaldehyde resin, were derived from coal tar and methanol, respectively, and blended to create Bakelite, a chemically resistant and non-melting plastic.

Acrylonitrile Butadiene Styrene (ABS Plastic): Uses, Properties

It is a preferred choice for structural applications due to its physical properties.

Plastic, What is it and what is its usage?

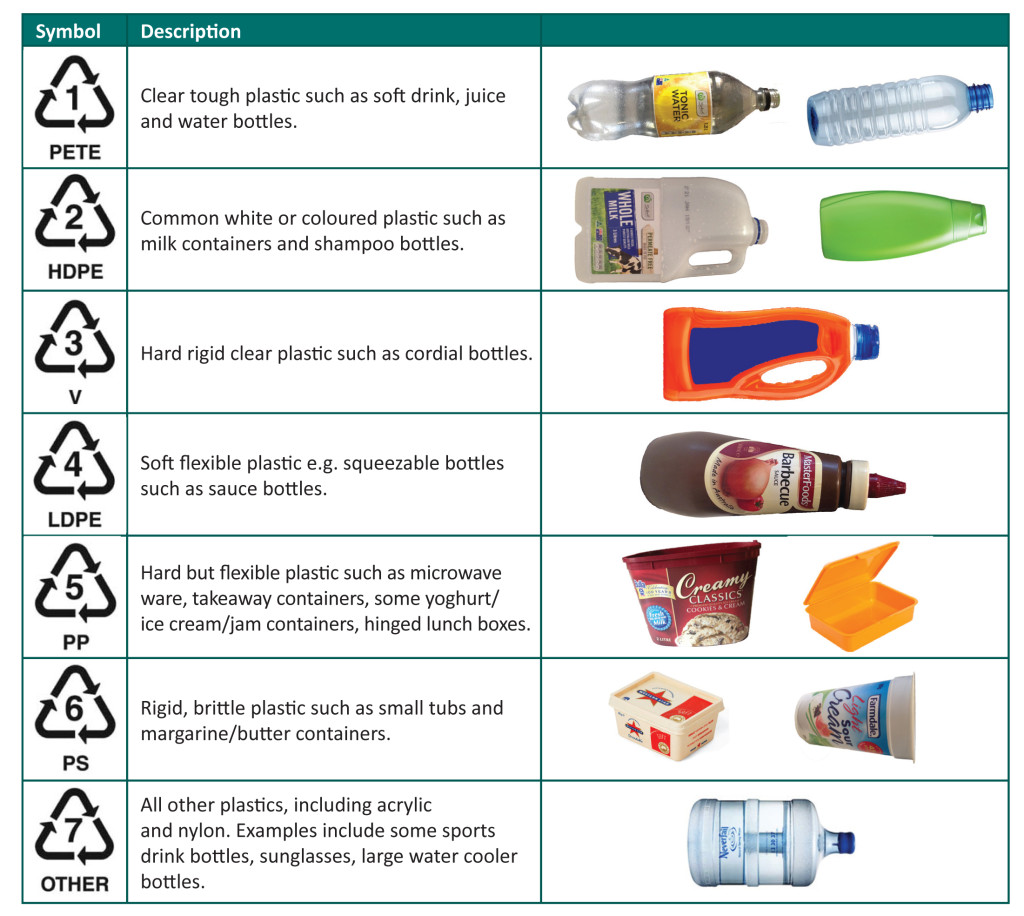

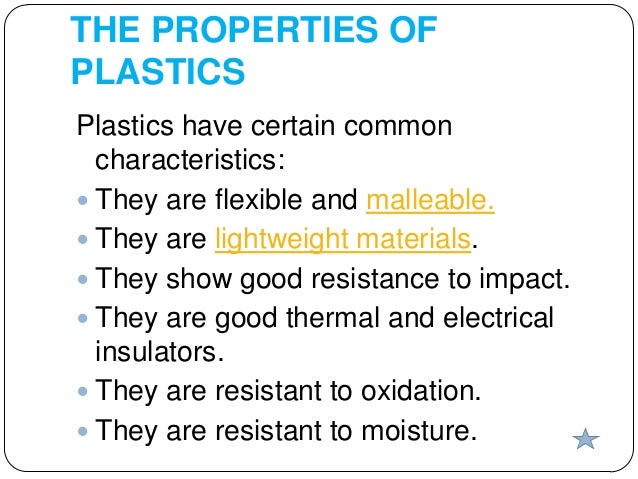

Properties of plastics and their application. High Impact Strength – PC has a high strength that makes it resistant to impact and fracture. Antistatic agents help to prevent the build-up of a static charge on a . Biodegradable plastics may serve as a promising approach to manage the issue of environmental accumulation of plastic waste in the ocean and soil. These properties include high rigidity, resistance to impact, abrasion, and strain.The most popular types of commodity plastics known today are polyethylene, polypropylene, polystyrene, polyvinyl chloride, and polyethylene terephthalate. These are substances added to improve the properties of a material, for example to add colour or elasticity or to reduce flammability. Plastics, also called polymers, are produced by linking together small building blocks, or unit cells. It is a tough plastic, easy to shape . PLA has a high glass transition temperature in the range of 55-60°C. Chemical resistance: The chemical resistance of a material should be considered in order to ensure it won’t be degraded by any chemicals . Durability: PVC is resistant to weathering, chemical rotting, corrosion, shock, and abrasion. Good transparency and wear resistance.Environmental concerns over waste plastics’ effect on the environment are leading to the creation of biodegradable plastics. Perspex and Rohm Plexiglas are both ideally suited to the manufacture of light guides & lenses.

Mainly used for compression moulding, extrusion, and injection moulding. It is the preferred choice for many long-life and outdoor products.This makes it suitable over glass, PMMA, and PE. It’s made of chains of styrene monomers and is characterized by its insulating, durable, and thermally stable properties.

These polymers give the plastic its properties.

What is Tritan? How Does it Compare to Other Plastics

Good insulation and low thermal conductivity. Poor dimensional stability and can be easily deformed.Most common plasticiser chemistries include citrates, benzoates, ortho-phthalates, terephthalates, adipates, azelates, sebacates, and trimellitates.Discover the properties of LDPE which makes it one of the most widely used plastics around the world.

Properties of Plastics

Acrylic – used in car headlights and as a glass alternative. The key properties of polycarbonates include: Toughness – Polycarbonate maintains a toughness value between -20°C to 140°C. Thermoplastics can be melted repeatedly, while thermosets can no longer be melted once the initial product is . Almost all the PLA’s commercial products are semi-crystalline and have a melting point of 180°C. Consider their chemical properties and benefits, too: PET or Polyethylene terephthalate – This plastic is ideal for food storage and water bottles.It is made of three monomers: acrylonitrile, butadiene, and styrene. The supreme optical properties make it one of the clearest plastics on the market.Properties of Plastics. It makes plastic ideal for the production of packaging materials, bottles or building and insulation materials. Polymers and derived plastics are generally good electrical insulators and some, such as polytetrafluoroethylene, are excellent.

Engineering-Grade Plastics: Properties and Applications

Homopolymer materials have good tensile strength and fatigue strength but are not easy to process. These properties have made it a key player in: construction, electronics, packaging, and the automotive industry. Biodegradable plastics are the type of polymers that can be .Engineering-grade plastics offer high-performance capabilities and upgraded characteristics compared to other plastic grades.One of the best things about HIPS plastic is that it’s very low weight, thus HIPS goods are easier to handle and transport. It is important to under-stand these standard terms since they are used by sup-pliers and users to communicate how a material behaves .Fundamental Properties of PLA Plastic .Acrylic plastic is extremely transparent, offering excellent light transmission properties and offers excellent optical clarity (when either MOP or vapour polished) similar to glass and is able to transmit 92 percent of white light.The mechanical properties of polymers are: Polymers have the ability to stretch and deform under load and recover unaltered when the load is removed. They can be complex combinations of different blocks.Plastic is a material consisting of a wide range of synthetic or semi-synthetic organic compounds that are malleable and, therefore, can be molded into solid objects.Commonly used injection molding plastics are tough and elastic materials with excellent creep resistance, geometric stability, and impact resistance even at low temperatures.Explore how the properties of polymers depend on their structure and different types of intermolecular bonds using this lesson plan for 16–18 year olds. It is produced from the monomer methyl methacrylate.Plastics are (mostly) synthetic (human-made) materials, made from polymers , which are long molecules built around chains of carbon atoms , typically with hydrogen, oxygen, sulfur, and nitrogen . With its high strength, rigidity and durability, POM plastic. It is commonly used for things like storage bags, too.POM, which stands for polyoxymethylene, is a high performing engineering thermoplastic that belongs to a group known as acetal plastics.

Low-density polyethylene (LDPE): Properties and Uses

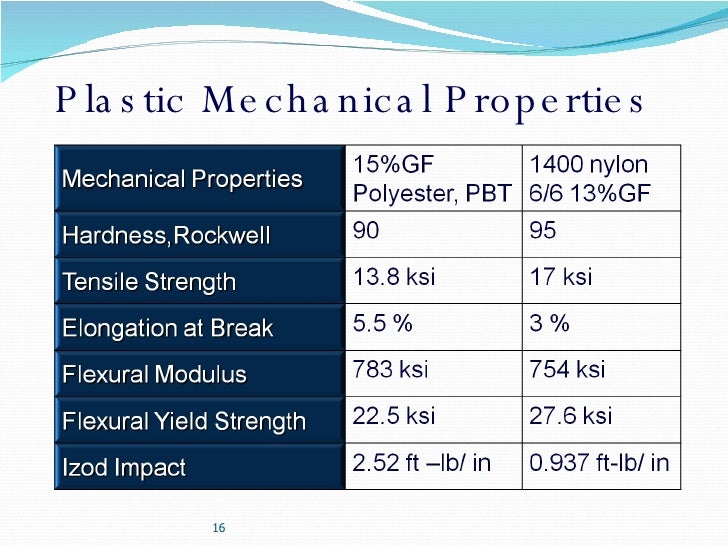

Plastics can be found in our houses, clothes, cars, toys, screens, medical equipment, etc.Mechanical properties: Different engineering plastics possess different properties, such as strength, rigidity, and fatigue resistance, which should be taken into account when selecting a material.PROPERTIES OF PLASTICS Mechanical and Physical Properties of Plastics This section will acquaint the reader with the tech-nical terms and concepts used to describe the properties or performance of a material. HDPE is highly prone to .Polyethylene terephthalate (PET) and High Density Polyethylene (HDPE) have some notable differences. This makes it suitable for applications that involve exposure to heat, such as automotive parts or electronic enclosures. Durable, water-resistant and available in many colours – but is easily scratched and not .Polylactic acid or polyactide (PLA) is a biodegradable and bioactive polyester made up of lactic acid building blocks. Each density gives the final plastic unique physical properties.When we look everywhere around us, we must find plastics.Another notable property of plastic ABS is its excellent heat resistance. Everything from your toothbrush to your hairbrush, your water bottle to your baby’s feeding bottle, the .It is the most common plastic on earth and can be manufactured in different densities. By using lactide as a raw material and . The monomer ethylene (C 2 H 4) n units link to form the polymer polyethylene (or polythene/PE).Strengths and weaknesses. Most polymers show some elastic behavior; some are extremely elastic.Plastics are composed of polymers, which are large molecules made up of repeating building blocks. Bisphenol A, or BPA, is a chemical used to strengthen plastics and resins and prevent them from breaking down over time.ABS plastics, or acrylonitrile butadiene styrene, are a versatile type of thermoplastic known for their exceptional strength and impact resistance.Plastic Property Descriptions. They are virtually unbreakable.

List of Commodity Plastics

As a result, polyethylene is found in a wide range of products. Plastics are also strong, long-lasting and light. Used in electronic housings, auto parts, consumer products, pipe fittings, and lego toys. Stress cracking: Polyethylene terephthalate (PET) bottles and containers have better resistance. Low Density Polyethylene (LDPE) LDPE has high ductility, but low tensile strength, making it more flexible than other plastics.

1 Material Properties of Plastics

Plastic comes in all shapes and sizes. For example, tensile properties of plastics such as plastic tensile strength and rigidity can be determined according to DIN EN ISO 527 by briefly applying load in one direction with a tensile test.

Properties

There are two main categories of plastics, thermoplastic and thermosets.Below are some of the specific types of plastics and how they are in use today.Plastic material properties are intended to represent the characteristic behavior of a plastic material during processing and in a product end-use environment. It does not leach into the food, but is sturdy and can be .October 5, 2023. What is ‘coefficient of friction’, ‘Izod impact’, or ‘tensile strength’? Review the list of material properties. They are term commonly used to describe a wide range of synthetic or semi-synthetic materials which is used in different applications. This is one of the reasons it is so useful. These properties may include better mechanical, electrical, and thermal properties; improved chemical and ultraviolet light resistance; and biocompatibility for food packaging applications. In addition, good transparency makes it suitable for various applications. Good impact resistance and they do not rust.Additives provide an extensive range of valuable performances to plastics: Plasticisers give flexibility, for example, in shower curtains or flexible tubes when added to PVC (polyvinyl chloride) Antioxidants help maintain mechanical properties under heat and oxygen ageing. Low-density polyethylene (LDPE): An Overview Because of its malleability, barrier characteristics, strong impact strength, and stress crack resistance, low-density polyethene (LDPE) has found widespread use despite its high clarity and .

What is Acrylic Plastic?

Plastics and pollution

Because of its high strength and durability, it is frequently used for mechanical components like gears, fittings, and bearings, and it is also put to use in outdoor settings .Properties of plastic .

Plastic is a material that can be formed into almost any shape.Polystyrene is a synthetic thermoplastic polymer used in plastics and material science. PMMA shows high resistance to UV light and weathering. Due to its transparency, PMMA is used in car windows, smartphone screens to aquariums. In this activity, polymers are used as illustrative materials for intermolecular bonds to help students to learn how the structures of polymers relate to their practical uses and properties. But, selecting the right plasticizer for an application has always been a daunting task. They make lives easier, safer, cleaner, and even more enjoyable. Plasticity is the general property of all materials that involves permanent deformation without breaking.Its main properties and benefits include: Electrical Properties: PVC is a good insulation material. Working properties.Plastics and pollution. Nearly all plastics are non-biodegradable.

What is PLA Plastic (Polylactide)?

Because of the polybutadiene it contains, HIPS has excellent impact resistance and can be used for products that will be subjected to rough handling or transit. They are light in weight and are chemically stable. They resist damage because they are so . During the early times, only low-density PLA was produced. The possible results and typical values . Most plastics are resistant to chemical and biological degradation, so they are durable. Hardness, Izod impact, light transmittance, tensile strength and more. There is no doubt that one of the most important properties of plastics is corrosion resistance. Bags, disposable dishes, insulating tapes, protective films and many other daily-use products .

What is PLA? Polylactic acid properties, uses, & melting point

Plastic materials: Types, composition and uses

Plasticizers are the most common additives used in the plastics industry. Copolymer materials have good thermal stability, chemical . It has a high melting point, allowing it to retain its shape and structural integrity even at elevated temperatures. There is soft and flexible plastic as well as very hard plastic that is nearly as strong as metal.

Advantages and disadvantages of HIPS plastic

Properties of Plastic

It is a transparent and rigid thermoplastic. It was first discovered in 1932 by Wallace Carothers by heating lactic acid under vacuum while removing condensed water.

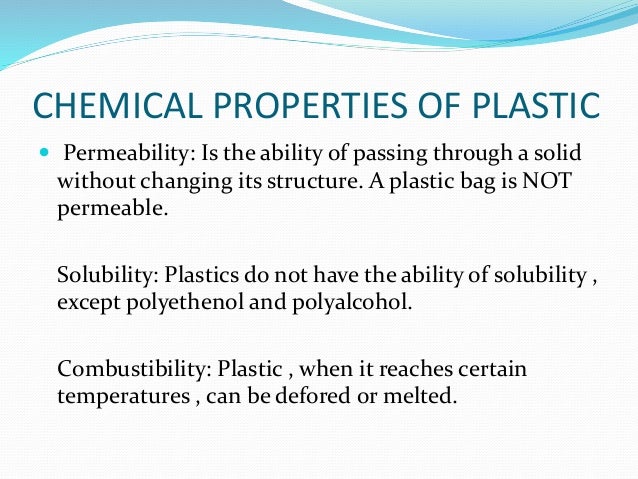

Bakelite: a plastic description.One of plastics’ most essential chemical properties is their resistance to degradation.Polymethyl methacrylate or PMMA is more popularly known as acrylic.

Polymethyl Methacrylate (PMMA)

These plastics possess properties that enable them to perform better in certain applications. This means that they will not rot away naturally either through the weather or by bacteria in soil, and can therefore cause a .Such properties can be investigated and compared between different products using standardized test methods.Plastics are made of polymers, which in turn are made up of many, sometimes thousands, of monomers. Those building blocks, which chemists call monomers, are made up of groups of atoms . BPA-Free Tritan. Delrin, a plastic that goes by several names, is used in everything from automobiles and medical equipment to household goods and computer devices. They exhibit good chemical resistance, making them suitable for a wide range of applications.

Plastics have coefficients of thermal expansion (4 to 20 x 10-5/°C; 2 to 11 x 10-5/°F) considerably higher than those of base metals (1. Easily moulded into different shapes and sizes. ABS plastics are commonly used in the automotive industry for interior and exterior parts, as well as in . HIPS is well suited for use in packaging since it maintains . These various properties can be obtained by modifying the production process, for example by varying the temperature or pressure at which the plastic is processed or adjusting the types of . Thanks to its good dielectric strength. Many plastics contain additives. Appearance: PET is a clear plastic while HDPE is opaque.Delrin Material Properties .

Injection molded plastic: Physical and mechanical properties

Material Properties of Plastics 1. Silicone, epoxy resin and other plastics are used mainly as low-pressure extrusion packaging electronic components and casting moulding. Engineering-grade plastics are able to endure a wide range of temperatures, significant mechanical stress, .1 Formation and Structure The basic structure of plastics (or polymers) is given by macromolecule chains, formulated from monomer units by chemical reactions. The melting point of acylic is 320 °F (160 °C). Afterwards, try our interactive plastic properties table to sort, compare or find out more about a specific plastic .Acrylic plastic sheets are easy to process and blend with organic solvents and adhesives. If a plastic product is to be used in a demanding environment where temperature, humidity, chemical resistance, and creep are critical variables, it is important to match the environment .

Plastics: A simple introduction

Polymers have the ability to permanently or viscously stretch and deform under load.Thermosetting plastics are phenolic, amino (melamine, urea-formaldehyde), polyester, polypropylene phthalate, etc. Film for wrapping candies and garments (called polybags) are also made from PP. Polymers’ name is derived from their elastic and plastic properties. Here’s the most common properties associated with these: #1 Polyethylene. Typical reactions for chain assembling are polyaddition (continuous or step wise) and condensation polymer-ization (polycondensation) [1] (Figure 1.5 x 10-5/°C; 0. Both these plastics are excellent packaging materials.

BPA becomes a problem when it leaches into . Engineering plastics are specially designed and formulated to have improved properties compared to commodity plastics. PLA material boasts high strength, density, and stiffness, comparable to polystyrene(PS) at room temperature.

What are plastics?

However, this feature is also accountable for their prolonged existence in the environment since they can take hundreds of years to break down naturally.Its key useful properties are its resistance to both impact and moisture.

- What Are Some Famous Wow Guild Names?

- What Are The 3 Parts Of A Magazine Article?

- Wetterfestes Holz Versiegeln | Holz versiegeln: Wissenswertes & Tipps

- What Birds Live In Arizona? : Sonoran Desert Birds · iNaturalist

- Wetter Schleswig Holstein Karte

- Wettervorhersage Nienhagen : Wetter Nienhagen bei celle

- Wetter Karneval Köln , Karneval in Köln 2022: Wetter, Rosenmontag, Regeln

- What Are The Different Types Of Aeroponics Systems?

- What Are The Chances Of A Shiny Pokémon Hatching?

- What Are The Treatment Methods For Psychiatric Erectile Dysfunction (Pe)?

- Wetter Limone Sul Garda Mai – Das Klima von Limone sul Garda und die beste Reisezeit

- What Are The Best R – R&B Music: Top R&B Songs

- What Are The Most Popular Driving Sim Games?