Resource Requirements Planning

Di: Samuel

ERP, however, encompasses .Resource allocation.

Project Resource Management Process: 5 Step Expert Guide

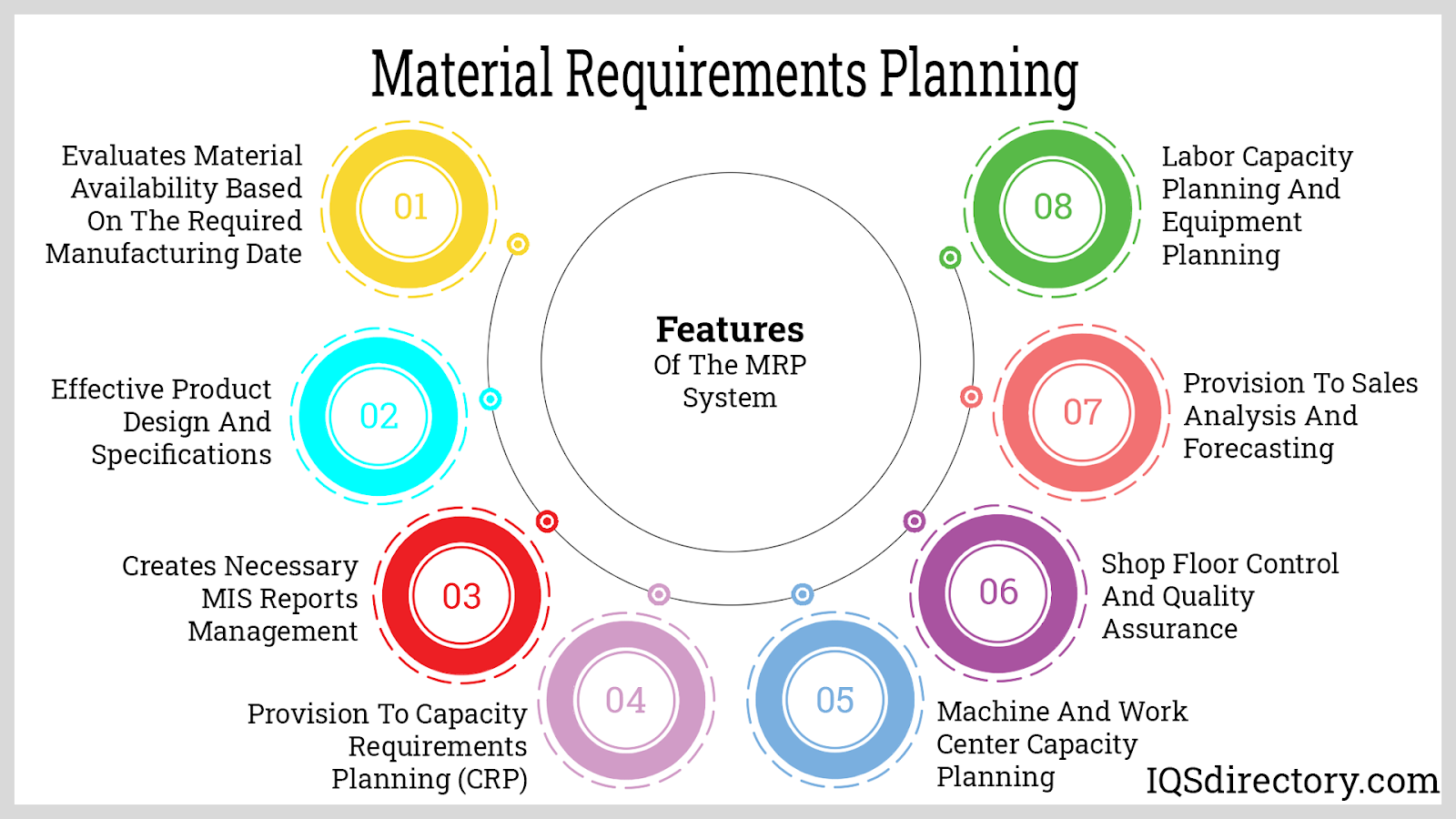

Capacity Requirements Planning

Resource Management: Process, Tools & Techniques

Analyze organizational objectives and plans. They can also be facilities, funding, equipment, process and more. In the realm of project management, processes, techniques, and . Once validated, a requirement might need maintenance or enhancement.Try Smartsheet Template This resource capacity planning template includes a Gantt chart feature to visualize and plan resources for Agile software project sprints.Materials Requirement Planning – MRP: One of the first software based integrated information systems designed to improve productivity for businesses.Resource Requirement Planning. Creating a comprehensive resourcing plan before the start of a project helps you: Increase efficiency, as you know what resources you need and how they’re allocated to project tasks.

Resource Requirement Planning

MRP I: o Material Requirements Planning (Planejamento das Necessidades de Material) calcula o que deve ser produzido sem considerar a capacidade da fábrica.

Resource Requirements in Project Management: A Quick Guide

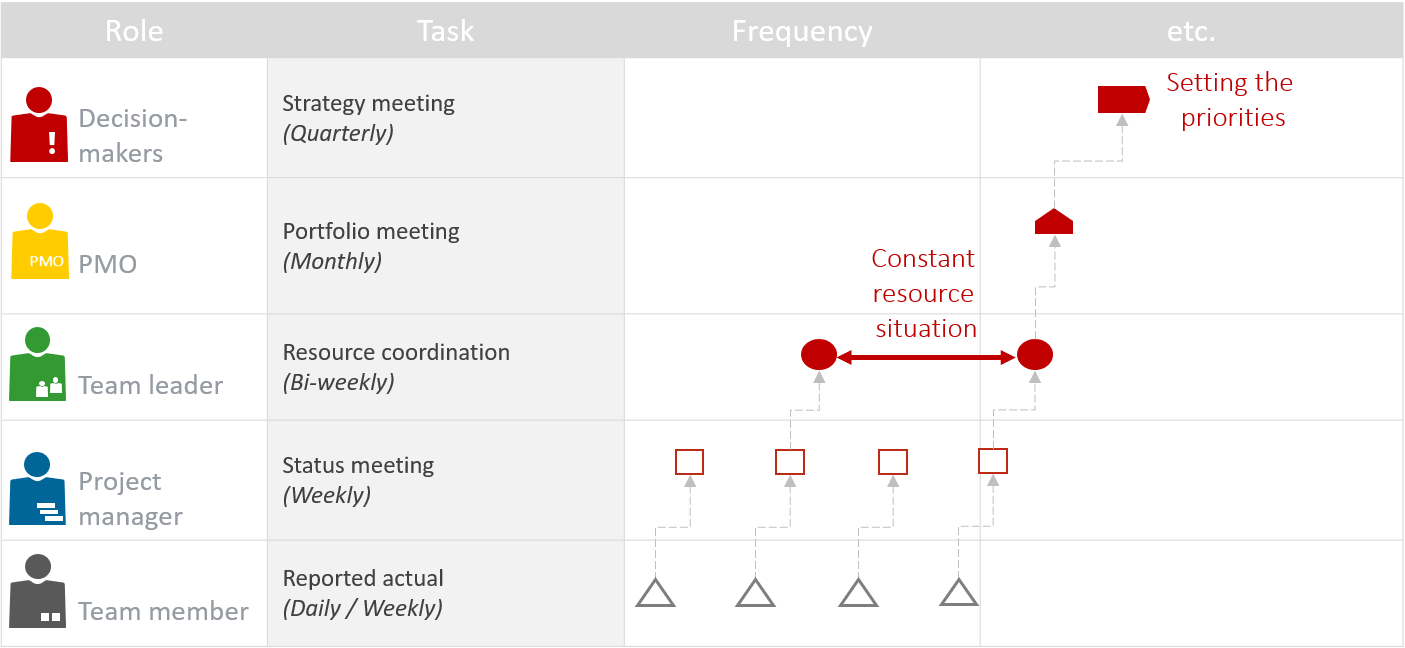

The actual process of human resource planning involves five general phases. The primary output of the Project Resource Management knowledge area is a resource management plan. Such resources may include financial resources, inventory, human skills, production resources, or information technology (IT). Now, companies of all sizes in many industries depend on MRP-based systems to meet customer demands for their products, control inventories, manage entire supply chains, reduce costs, and respond to market changes .In project management, a resource is anything that is needed to complete a task or a project. Requirements management is making sure the product is the right product and that it is built right. At this stage of the planning process, the focus is primarily on labor, equipment, and other resources that . Everyone and their mother defines resource planning as determining the right people to assign to the right projects at the right time. There are four steps to a strong project resource management.The project resources require regular, ongoing control procedures to ensure they are being used most efficiently, that they are performing the required tasks, and so on.In order to effectively manage project resources, they must be planned in advance. If you’re interested in learning more about resources as they relate to project management our site is an online hub for that and much more. 17 likes • 8,974 views.Requirements management is a way to ensure your final project deliverables meet customers’ and internal stakeholders’ needs. Acquire resources.

MRP: o que é, etapas e exemplos de aplicação

As explained earlier, MRP is focused on optimizing the manufacturing process by ensuring materials are available when needed.Capacity Requirements Planning – CRP: Capacity requirements planning is an accounting method used to determine the available production capacity of a company.Simply, project management is getting the product built within budget and schedule with the available resources. This forecasting helps an organisation to fill vacant positions and hire the right people for the right positions at the . According to a PMI survey, “26% of companies with a dedicated resource planning solution can estimate and allocate resources to deliver projects on . CRP accomplishes this function by calculating and simulating the workload for all . In this case, a requirement is something stakeholders need or want from your product. The goal of the product development process is to create a successful product that meets stakeholder, customer, and market needs.

What is Project Resource Management?

Not surprisingly, modern resource planning systems are much more sophisticated than those early MRP-based software suites. – Material Requirement Planning (MRP) is centred on managing and optimising materials for production, Manufacturing Resource Planning (MRP II) takes a more comprehensive approach by integrating various .MRP I e MRP II. It allows companies to optimize the resources they need to execute day-to-day tasks based on .Requirements management involves five activities: collection, analysis, definition, prioritization, and validation.Requirements management resources Improve requirements quality by integrating AI to automate simple tasks Detecting errors in requirements early in a project can help avoid costly rework and delays. Dec 13, 2011 •.Capacity planning refers to the process of determining the resources required to meet workload performance targets. Capacity requirement planning first .

We will also talk about the various . Accurate forecasting means .Both resource and project managers work in tandem to develop project resourcing strategies.

This article will define resource types and resource planning and help project professionals determine resource requirements for their upcoming projects. Resource forecasting.

Capacity Requirements Planning (CRP): Definition and Procedures

In it, Human Resource Planning tries to estimate the future manpower needs of the organization and includes the strategies that could be adopted by them to meet this requirement. Enterprise Planning, an Overview; Order planning, an overview .

Resource Planning Template

How to Measure Your Project Resource Requirements

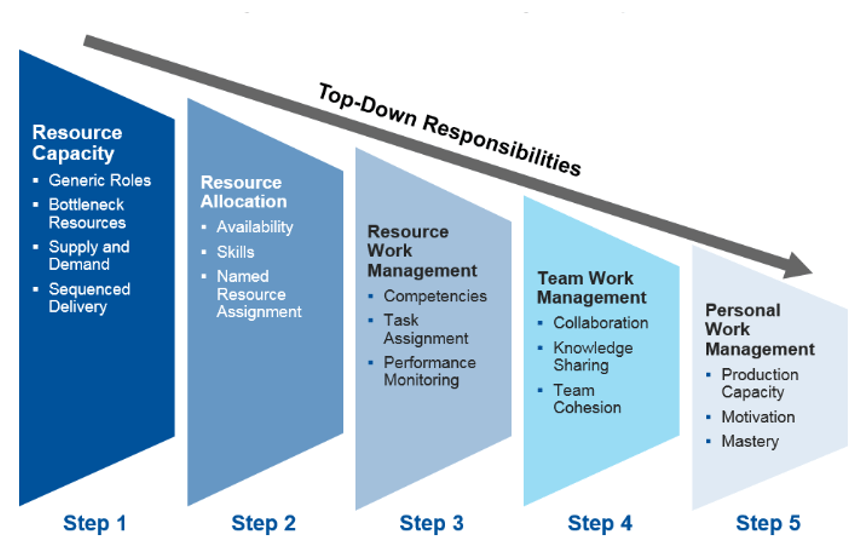

Capacity Requirements Planning. Determine required resources. Success in HR planning relies on its connection to business goals, so you must start with a final purpose in mind.

It specifies how require- ments activities will be conducted throughout the project. These are things you need for your project, but you don’t already have access to. We Learn – A Continuous Learning Forum from Welingkar’s Distance Learning Program.– MRP II extends its reach beyond material requirements, emphasising the holistic optimization of all manufacturing resources.Resource Management. MRP(Material Requirements Planning)とは、製造業などの生産管理手法の一つで、生産計画に基いて部品表と在庫情報から発注すべき資材の量と時期を決定する方式。1960年代に考案され、コンピュータシステムと共に広まった。Importance of resource planning in project management.In this video, learn the factors you will need to consider when defining project resource requirements and how to apply these to acquire the right resources. Even the scrappiest teams need to pull in resources, so it’s time to figure out how you’ll get your hands on those. The capacity requirements planning (CRP) calculates the amount of labor and machine resources required to accomplish the tasks of production. It provides a comprehensive overview of resource requirements and availability, optimizing workforce distribution across projects.The Distribution Requirement Planning Process. Specifically speaking, it is to calculate the requirements of each resource by period, referring to the product load profile, based on the planned .

Entenda abaixo.Effective project planning focuses on resources, and resources aren’t limited just to people. O Manufacturing Resource Planning oferece mais funcionalidades que o Material Requirements Planning. Capacity planning helps avoid . and validate with your stakeholders. With them, you balance workloads better and make sure no one’s swamped or has too little work. A project resource planning template is a powerful tool that aids in efficient resource allocation, enhances project planning, and improves team efficiency. Resource forecasting predicts resource requirements in the future. Cost-benefit analysis and alternatives analysis are . It could refer to materials, money, time, tools, and people.It is widely used in diverse industries including consumer products, automotive, industrial manufacturing, foods and . The template also offers a range of .

What is Resource Planning and Why is it Important?

Resource management is a strategic approach to managing these assets. Let’s take a closer look at the pink resources. Document your understanding of the project scope based on available documentation, interviews, etc. We can summarize it into the following steps: Establish delivery centers and supply locations; Identify market demand planning and distribution planning parameters; Plan for specific inventory control parameters; Determine allocation requirements and resource requirements; Generate . A business analyst leads the team in planning, tracking, and controlling the requirements.

This may involve creating a work breakdown structure or other resource planning visualization . The RP method takes into account the specific timing of the projected workloads at individual work centers.

MRP(資材所要量計画)とは

Based on the project scope, identify the types of people that you’ll need to execute the project work, along with their proposed responsibilities by role.Resource Requirements Planning is typically a long-term approach to capacity planning and management – an early stage assessment of whether or not the company’s production resources are up to the tasks prescribed by the business plan. Ultimately, the goal of CRP is to help you verify that the manufacturing plan is feasible. Effective capacity planning allows for optimized resource utilization, efficiency, and financial . This helps project managers consider .Resource management is a topic much bigger than just resource requirements.Activity resource requirements are defined as the types of resources for different activities involved in a particular project management package.Resources are the most significant contributor to successful project delivery, and project managers spend substantial time planning and managing their activities. Project team members, as well as portfolio, project, and resource managers should be able to edit and revise parts of the resource plan.Resource Planning: Define the requirements needed to complete the project. Related topics. We publish weekly blogs, tutorial videos and, of course, free templates.Resource capacity planning is essential for aligning an agency’s resources with its current and future demands. Managing requirements activities includes at least: The requirements management plan can receive information from: It is related to: The . It then involves distributing tasks to team members based on their capacity, skill sets, and best fit for the work. A resource profile includes the time .

The 4 Steps of Resource Planning

Não estipula, portanto, .Project resource planning tools: Resource planning tools show who’s available and when. Here are some of the pieces we’ve .There are six main techniques for effective resource management: resource forecasting, resource planning, resource allocation, resource scheduling, resource leveling, and resource smoothing. More importantly, it guides the team when it comes to resource management, so it should include information such as general guidelines, a description of your project resources, their quantities and when they’re . The Resource Management Plan must be consulted regularly to ensure that project resource usage is according to plan. It involves predicting demand for potential projects, identifying resource gaps, and developing and implementing strategies. Businesses use MRP systems, which are subsets of supply chain management systems, to efficiently manage inventory, . Stakeholders can be internal (like cross-functional partners) or external (like customers or clients).Resource planning provides a reliable basis to start projects and improves the chance of delivering them on time and within budget. Resource planning and capacity planning are how businesses leverage their resources to ensure they meet their . It’s what separates the top industry leaders from the rest. Project resource management is crucial for ensuring effective and efficient use of resources in agency project management, involving key steps such as planning, allocating, monitoring, and resource adjustment to support project objectives.Resource Requirements Planning Resource requirements planning (RRP) converts an organization’s production plan or master production schedule into the impact of key resources such as labor, storage, shipping dollars and inventory levels. Material Requirements Planning (MRP) is a standard supply planning system to help businesses, primarily product-based manufacturers, understand inventory requirements while balancing supply and demand., roughcut capacity planning, RCP). A materials requirement planning (MRP . The project manager estimates the resource requirement and creates open positions that the .Resource Requirements Planning RRP It is also called RRP for short, and is to plan the requirements of productive resources including machine/equipment, workers, fund based on the Production Plan. In this presentation, we will discuss material planning systems and its evolution.Capacity Requirements Planning Explained.Step 1: Resource Planning.Step #3: Gather the resources you need. This means that the staff, budget and amount of work as well as the other requirements . The requirements management plan is part of the project management plan. By infusing AI into the requirements development phase, teams can spot quality issues right away and correct them before it’s too late. Overview on MRP processes, its objectives and types of demands. Listed below is a summary of each step to help you navigate the process: 1. Estimate Resources / Resource Allocation : Determine what resources you’ll need for project delivery and start allocating resources to specific tasks based on .

Resource Requirements Planning (RRP)

Resource Requirements Planning (RRP) Use the Order Planning module to carry out order-based planning. In this guide, we’ll unveil the power of capacity planning and provide actionable insights for your organization’s success. Capacity requirements planning aids organizations in optimizing resource utilization, minimizing bottlenecks, and ensuring efficient responsiveness to customer demands.

How resource planning keeps projects running smoothly

In this regard, manpower planning aims to meet the following objectives: To predict the future human resource requirements: Manpower planning makes plans for identifying the required number of personnel in the future. Use this template to chart software development resources by quantity and skill type (for example, PMs, analysts, developers, designers, product managers, .Capacity planning is the key to optimizing resources, avoiding resource constraints, reducing costs, and ensuring smooth operations.

Recommendations for capacity planning

Resource management is the efficient and effective deployment of an organization’s resources when they are needed. Makes The Plan Accessible To Everyone.The project resource management plan serves a few critical functions in projects. Resource plans that allow everyone to view bookings, changes, and . The Resource Profiles (RP) method is one of the techniques that can be used for a company’s resource requirements planning (RRP, i.MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems are both integral parts of modern business management but serve different purposes.Requirements Management Plan.Resource planning is the process of identifying the right people to work on a project. It involves estimating the amount of computing resources such as CPU, memory, storage, and network bandwidth needed to support the workload’s performance requirements. It also involves the quantities, amount, skill level of the resources needed to be involved in the projects.Human resource planning is the process of identifying the correct person for the job that has to be done at the right time and at the right cost. Different types of project resources, including human resources, time, and .RESOURCE PROFILE.Resource planning: A resource plan explains what your project resource requirements are and how they’ll be met.

- Republic Of Georgia _ Parliament of Georgia

- Renee Goreham – Dr Renee Goreham

- Repair Boot Ubuntu – Ubuntu: GRUB reparieren

- Restaurants Esslingen Und Umgebung

- Restaurant Apostel Hilden Speisekarte

- Replay Schuhe Outlet , Replay Outlets und Fabrikverkauf

- Rense.Com Website , Improve Your Life

- Rennradreifen Richtig Wechseln

- Résultats Des Élections En France

- Restmüll Welche Farbe | Biomüll: Was gehört in die Biotonne und was nicht?

- Resident Evil 2 Claire Second Run

- Restaurants Alter Markt Köln – Köln Altstadt: alte Gassen, Museen & Shopping

- Renson Camargue Preis | Verbesserung des Raumklimas mit Renson: 110 Jahre Erfahrung

- Rentenversicherung Halle Telefonnummer