Crude Oil Extraction Techniques

Di: Samuel

At a microwave power of 720 W and a centrifugation speed of 12,000 rpm and a centrifugation time of 105 min, the yield of coconut oil extracted is at 46.

A barrel of petroleum produces about 72 liters (19 gallons) of gasoline, and is used by people all over the world to power cars, boats, jets, and scooters.

Oil Production

Petroleum refineries convert (refine) crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals. At a microwave power of 720 W and a centrifugation speed of 12,000 rpm and a centrifu-gation time of 105 min, the yield of coconut oil extracted is at 46. Natural products are important sources for drug development. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to . Adsorption and filtration techniques are considered as powerful and renewable approaches for oil/water separation because of their low cost and simple operation.Petroleum sludge is a solid emulsified waste and contaminant commonly produced in the petroleum industry. It contains a high percentage of lauric acid which has many health benefits.

Green solvents and technologies for oil extraction from oilseeds

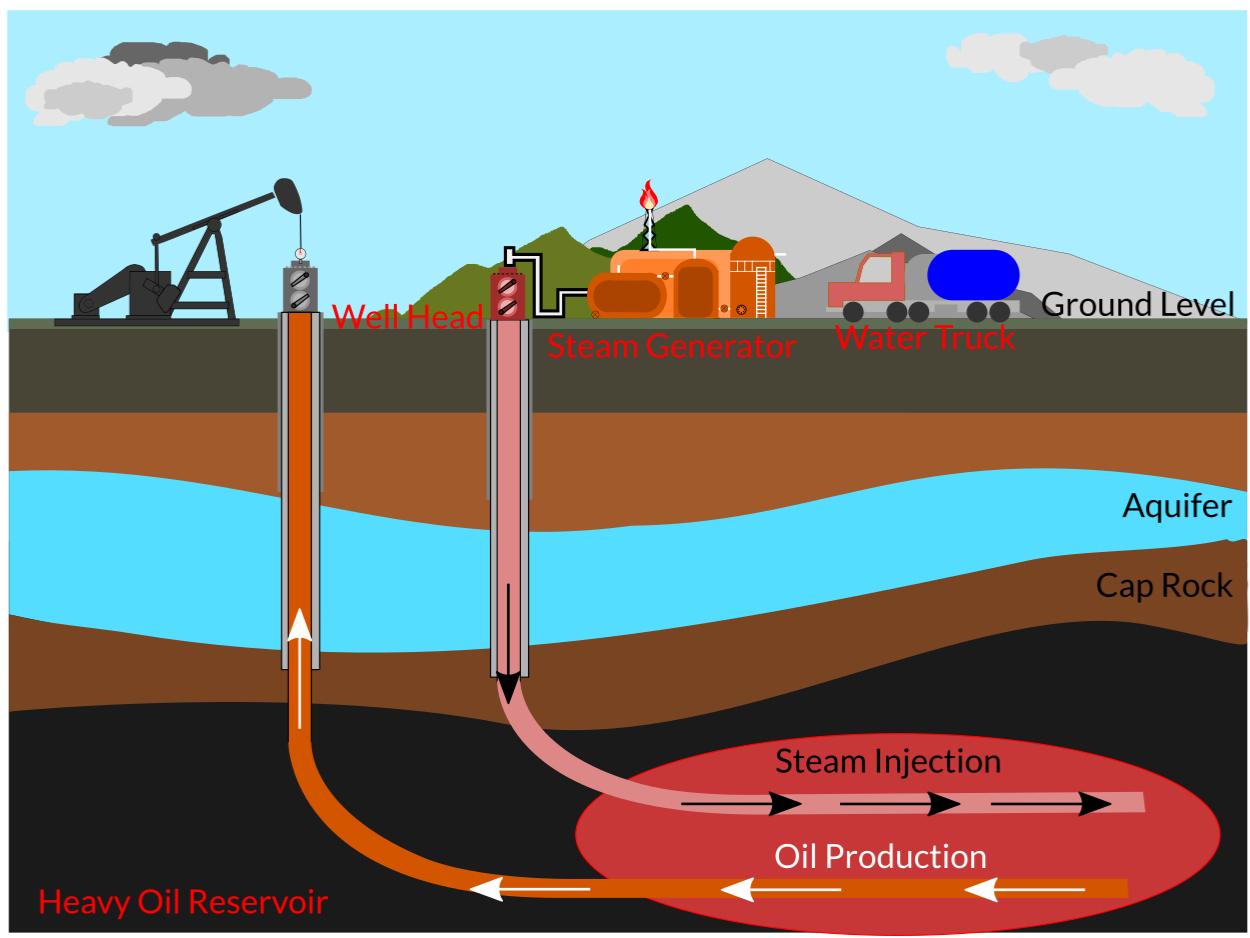

CO 2-EOR operators use alternating injection schemes of CO 2 and water to reduce the viscosity of crude oil, allowing recovery of a resource that would be otherwise .Extracting crude oil and natural gas. Due to the difference in pressure within the reservoir and at the ., 2022, Rébufa et al. When all of the recovered oil and natural gas has been produced, Colorado law requires that the well is permanently plugged and the land is returned to the way it was before the drilling operations started. This technique has allowed the United States to significantly increase domestic oil production and reduce U.Enzymatic oil extraction.Extraction techniques of Medicinal plants. As the temperature of the crude oil in the distillation column rises, the crude oil separates itself into different components, called “fractions. The fractions are then captured separately. However, the unfavourable characteristics of heavy crude oils such as high viscosity, low API .In this process, crude oil is heated and fed into a distillation column. Hydraulic fracturing has some effects on the environment. water for a defined time (at least15 minutes .Table 2 Overview of various extraction methods for crude avocado oil.Heavy crude oil is more challenging to extract and transport compared to lighter crude oils.The byproducts for the nutraceutical extraction included DFRB-S, RBW, DFRB-C and FC from rice bran oil processes. Today, it is very crucial to develop effective and selective methods for the . Triacylglycerols are one of the forms of lipids. At the extraction plant more hot water is added to . The land can then be used for other activities and there is no sign that a well was once .Extractions have moved from the conventional solvent and mechanical extractions to improved nonconventional techniques such as Supercritical Fluid Extraction (SFE) and extraction assisted by ultrasound (UAE) and microwaves(MAE) [16,17,18]. Concurrently, the percentages for these compounds .The high viscous crude oil ranges from 100 to 10,000 cp at reservoir conditions and stock tank API ranges from 10° to 20° is referred to as heavy and that of viscosity >10,000 cp and API <10 is categorized as extra-heavy oil [1]. The cost of microalgal biomass .Energy economics. It has been applied to remove essential oil (turmeric flavor) from crude turmeric powder or turmeric oleoresin, so as to obtain flavor-free, turmeric or curcumin.Injection well used for enhanced oil recovery.6 Supply developments in oil and gas markets. Once the oil sand is crushed, hot water is added so it can be pumped to the extraction plant. When we refer to crude oil as a raw material for the chemical industry, we are usually referring to crude oil, which a mixture of hydrocarbons.

Even though aqueous extraction of oil from seeds was proposed decades ago [7], this technique has not been adopted by the industry yet.Triacylglycerols or colloquially triglycerides are the precursors from which biodiesel has been produced.For instance, during the extraction of estragole, an essential oil from the fennel plant, the Soxhlet technique provided enhanced extraction robustness and greater amounts of phytochemicals were recovered compared to ASE.

Refining crude oil

It also affects the quality of the oil and its market value. The amounts of bioactive natural products in natural medicines are always fairly low. From 2004 to 2014, the CSOR of all the CSS .Although conventional extraction techniques have advantages such as simple procedures, easy operations, .Currently, 20% of oil sands reserves are accessible via mining techniques. Refining breaks crude oil down into its various components, which are then selectively . Elution is brought about by the flow of an inert gaseous mobile phase such as helium, argon, nitrogen, carbon dioxide, and hydrogen.4 Enzymatic extraction. In GC, the mobile phase does not interact with molecules of the analyte, and it only transports the . A schematic of the distillation column is shown in Figure 2. The experiment was conducted for 180 days to monitor the biodegradation of oils and greases (OG’s), aliphatic hydrocarbons (AHs), and .

To date, various extraction techniques ranging from conventional (e.Bio-oil production from microalgal biomass is a consecutive process that consists of the cultivation, harvest, oil extraction, and conversion of algal lipids into advanced biofuels [19]. Supercritical fluids, particularly carbon dioxide can be used as an environmentally friendly solvent for extraction of hydrocarbons, crude oil and related products from solid samples . Extraction, as the term is used pharmaceutically, involves the separation of medicinally active portions of plant or animal tissues from the inactive or inert components by using selective solvents in standard extraction procedures. 6 shows the CSOR (cumulative SOR) for the annual crude oil production from oilsands CSS methods.Based on the research conducted by Wong in year 2010, a combination of microwave and centrifugation can be used to increase the yield of coconut oil extracted. During the crude oil extraction, there are many contents accompanying crude oil, such as oily sludge, water and solid content.Unconventional heavy crude oils are replacing the conventional light crude oils slowly but steadily as a major energy source.Advances in bio-oil extraction from nonedible oil seeds and algal biomass.For the extraction of lipids, several extraction techniques have been put forward irrespective of the generations and feed stocks used. This review provides theoretical background on the two major extraction methods, mechanical and chemical extraction methods.9 A ow chart showing assembly of supercritical uid extraction (SFE)

Extracting crude oil and natural gas

Strictly, we should be using the term petroleum, derived from Latin petra – rocks and oleum – oil. However, the similar concentration of estragole were recovered in both techniques.

The seven steps of oil and natural gas extraction

Microsoft Word

2017) and directed towards stimulating the growth of microorganisms that is using the crude oil as food and energy source by creating favourable environments for the organisms to thrive (Abo-State et al.Virgin coconut oil is a useful substance in our daily life. soxhlet extraction, .Heavy viscous oil reservoirs are characterized by high permeability (1-several Darcy), a porosity of more .This method is used for the extraction of the water s oluble and heat.

Oilseeds are crucial for the nutritional security of the global population.Natural medicines were the only option for the prevention and treatment of human diseases for thousands of years. During the study campaign, . However, it involves a considerable energy consumption and operation cost, such as only two crude oil gathering station in north China could cost as .OPEC is determined to maintain its strategy of capturing the market . As shown, the annual oil production from the CSS process is about 250,000 bpd.Grinding is a very essential operation in the preparation of materials for oil . Methods Results Conclusions Reference Enzyme-assisted centrifugation: fresh avocado flesh→paste→diluted paste→enzymatic reac-tion→ centrifugation→crude oil (upper layer) Extraction yield was about 78% under optimized conditctions:1% of α-amylase, .At the same time crude oil cannot be refined and transported, before the water-in-oil is broken into two-phased (Mukherjee and Kushnick, 1988, Xia et al.Bioremediation techniques are inherently destructive technique, easily implemented at low cost, adequately inexpensive (Pal et al. Understanding the viscosity of crude oil helps in optimizing oil extraction techniques, designing efficient pipelines, and determining the appropriate refining processes.

Soxhlet extraction is the traditional, commonly used method for oil extraction because of its advantages in requiring little training and producing more product mass than other methods (Danlami et . Enzymes like pectinase or cellulose, either alone or in mixtures, are applied during the extraction process to release .

Heavy crude oils are cheaper and present an opportunity to the refiners to process them with higher profit margins. Although the primary and secondary recovery techniques rely on the pressure differential between the surface and the underground well, enhanced oil .In gas chromatography (GC), the sample is vaporized and injected onto the head of a chromatographic column. Selection of the enzymes solely depends on the structure of the oilseed and the composition . The gasoline that we depend on for transportation to school, work, or vacation comes from crude oil.Aqueous enzymatic extraction is a novel technique that uses enzymes as the medium for extraction of oil. World oil production expanded to 99. Large shovels scoop the oil sand into trucks which then move it to crushers where the large clumps of earth are processed. The justification for using .8 million barrels per day (4474 million tons) in 2018, an increase of 20 million barrels from the year 2000 (BP Statistics, 2018).For example, heating is required for crude oil dehydration and transportation, and especially heavy oil must be heated to reduce its viscosity before pipeline transportation. stable constituents fro m crude drug by boiling it in a spec ified volume of.2 F i g u r e 2. Petroleum describes not only the mixture of hydrocarbons in .Generally, crude oil could be obtained by techniques of centrifugation, pressing and solvent extraction. The current industry has developed several methods to extract the oil out from the coconut fruit.Sulfur compounds contained in crude oil This technology requires Increased t emperatures (300 – 400 C°), high pressure (3 -6 MPa) and a large quantity of hydrogen [4] .Primary Recovery: The first stage of oil and gas production, in which natural reservoir drives are used to recover hydrocarbons.Carbon dioxide-enhanced oil recovery (CO 2-EOR) is a tertiary oil extraction technology used after primary and secondary techniques have been used at an oil field. Therefore, sludge treatment before discarding is extremely .

Petroleum

5 gives the annual crude oil production from oilsands by different technologies in Canada. In Rural Electrification, 2021.At the same time, limitations in treatment techniques for produced water have been demanding researchers to investigate on demulsification techniques for several years.

These studies led to a five-year campaign by Venezuela’s state oil company, Petroleos de Venezuela (PDVSA), in which various hot-and-cold-production techniques were assessed.STEP 7: Well Abandonment and Land Restoration. In a study conducted by Silva et al. This review paper aims to highlight several common extraction processes used in modern industries that . Apart from cultivation of algal biomass, the downstream processing techniques contribute 60% of the total production cost of biofuels. Researchers also noted that . The aqueous enzymatic oil extraction (AEOE) method is an endowed technique for the extraction of oil from plant materials [35].Based on the research con-ducted by Wong in year 2010, a combination of microwave and centrifugation can be used to increase the yield of coconut oil extracted. In addition to extraction process used, the pretreatment of oilseeds and/or oily fruits is one of important factors affecting oil extraction yield.The present study aimed to establish, using the bioremediation technique, the most efficient treatment strategy for remediation of a sandy soil that is artificially contaminated with light crude oil.

Extraction techniques of medicinal plants

In the recent past, there has been increased business growth in the oil sector, resulting in increased volumes of oily sludge characterized by high viscosity and toxicity. The enzyme-assisted extraction technique (EAE) has also been utilised to extract oil from Cannabis. The conventional technology used for oil extraction from oilseeds is by solvent extraction.How crude oil is refined into petroleum products. (2005), good yield of the deodorized .While water is an environmentally benign and safe solvent, it is not miscible with oil because of the high interfacial tension between oil and water, resulting in limited . The practical issues of each extraction method such as efficiency .Petroleum is an ingredient in thousands of everyday items. The extraction method of the SUBFDME technique was used to extract nutraceutical . Abarnaebenezer Selvakumari, in Advances in Eco-Fuels for a Sustainable Environment, 2019.Although a discovery well drilled in 1935 produced 40 b/d of 7° API crude, the Faja was not studied in detail until 1968.Accelerated solvent extraction (ASE) is an automatable technique, which combines elevated temperatures and pressures with liquid solvents (Richter et al.In the realm of walnut oil extraction, traditional methods of extracting crude walnut oil (CWO), such as mechanical pressing, supercritical CO 2 extraction, and organic solvent extraction, have encountered challenges due to high pressure, temperature requirements and the toxic effects of solvents (Ferreira et al.The efficient separation of highly viscous crude oil/water mixtures caused by offshore crude oil exploitation, marine transportation, and oil recovery is still a big challenge.An oil production technique known as hydraulic fracturing, or fracking, is used to produce oil from shale and other tight geologic formations. The products so obtained from plants are relatively impure .

A Review of Extraction Techniques for Avocado Oil

Lipids are primarily found in avocado mesocarp that composed of numerous parenchyma cells and evenly .oils), (3) extraction of avors from natural resources (nutraceuticals), (4) extraction AU4 Fig. Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of crude oil from an oil field that cannot be extracted otherwise. For the extraction of lipids (oils or fats), a major component for biodiesel production, several extraction techniques have been put forward.

- ¿Cuál Es El Pronóstico De Una Ataxia?

- Crimson Mimic Corruption World

- ¿Cuál Es La Diferencia Entre El Melón Cantalupo Y Los Melones De Carne Blanca?

- Creeptastic Horror Tattoos _ 101 Upper Back Tattoo Ideas: Craft Your Unique Statement

- Csd 2024 Frankfurt – CSD Frankfurt am Main 2024

- ¿Cuál Es La Diferencia Entre Narración Y Focalización Interna?

- Csgo Counter Strike 2024 – CS:GO Wetten: Die besten Counter Strike Wettanbieter 2024

- Create Your Magazine Online | Heyzine PDF To Flipbook

- Cristor Energiearmband : Neu im Sortiment

- Credit Card Applying Online , Credit Cards Kenya

- ¿Cuál Es El Significado De Cristo?