Cascade Control Examples : The benefits and challenges of cascade control

Di: Samuel

If you do not have a Simulink model of the control system, you can perform the same steps using LTI models of the plant and Control Design blocks to model the tunable elements.Joined: 7/24/2014.首先来看一下cascade control 串级控制的基本环路。. The output of the PIDE instruction is wired through the Deadtime and Lead-Lag and then back into the PV input of the PIDE.This session explains the difference between Feedback Control and Feedforward Control. How to successfully cascade your strategy. An example of a cascade control system is a temperature control system in a chemical reactor.

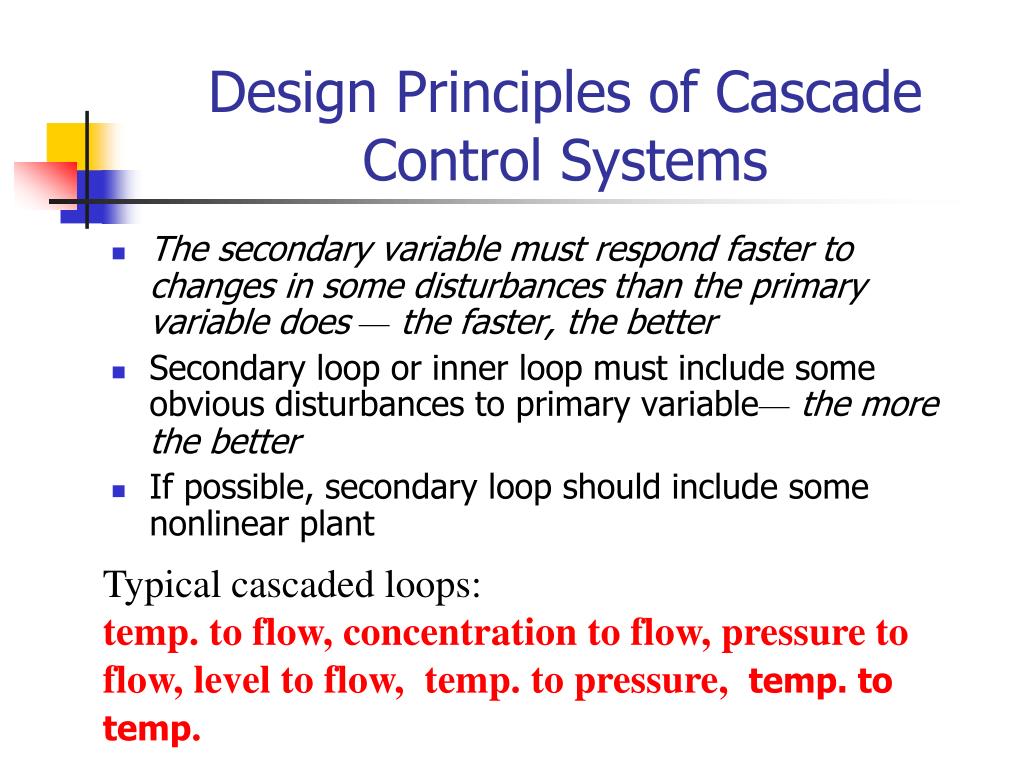

Designing Cascade Control System with PI Controllers

We will show an example in the next section.

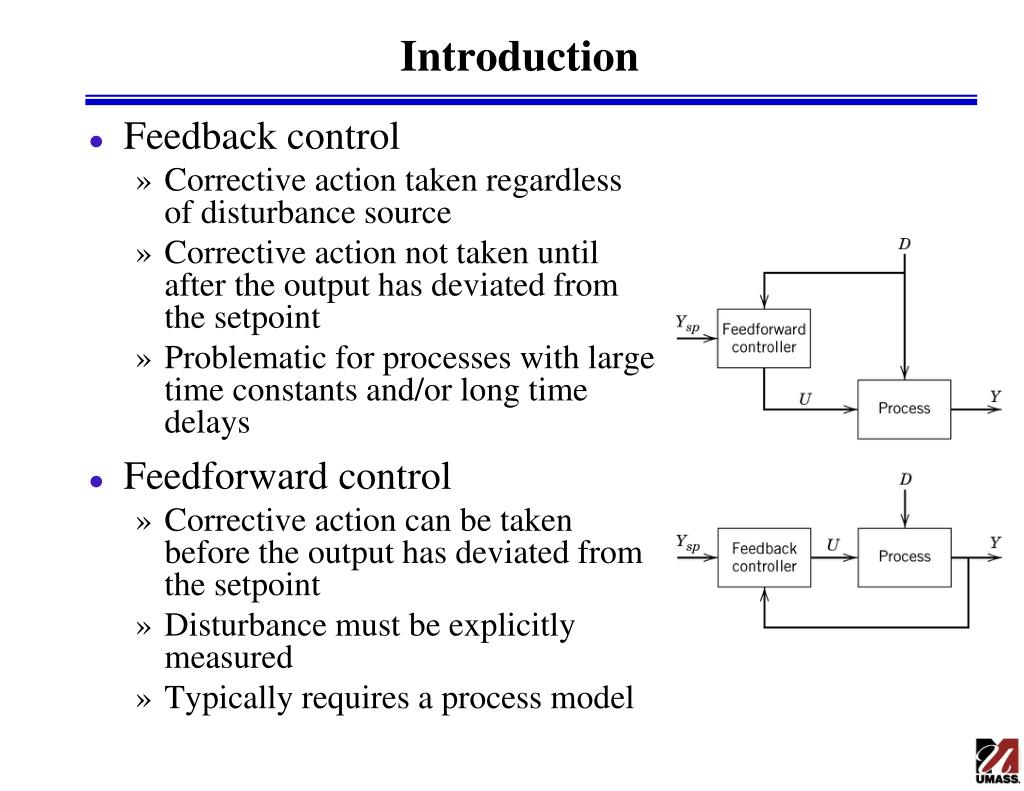

Orlando Arrieta, Ramon V ilanov a, Pedro Balaguer.For these examples I have renamed the files by adding stable_cascade_ in front of the filename for example: stable_cascade_canny. For example, if the controller adjusts the valve to change flow rate, but line pressure might also affect the flow rate, then control the flow rate to a setpoint. This second loop is responsible for making sure that the flow rate of the steam doesn’t change due to any uncontrollable . Last visit: 12/4/2023. “Feedforward” is a rather under-used control strategy capable of managing a great many types of process problems.Lesson 8: Cascade and Feedforward Control Schemes to have a feedforward controller that adjusts the set point of a feedback controller. The larger the organization is, the harder it is to implement a cascading strategy approach successfully. Here, you use Closed-Loop PID Autotuner blocks to tune two PI controllers in a cascade configuration.

Cascade Control Design Introduction

Cascade Temperature Control System.

What is a cascading strategy and how to implement one?

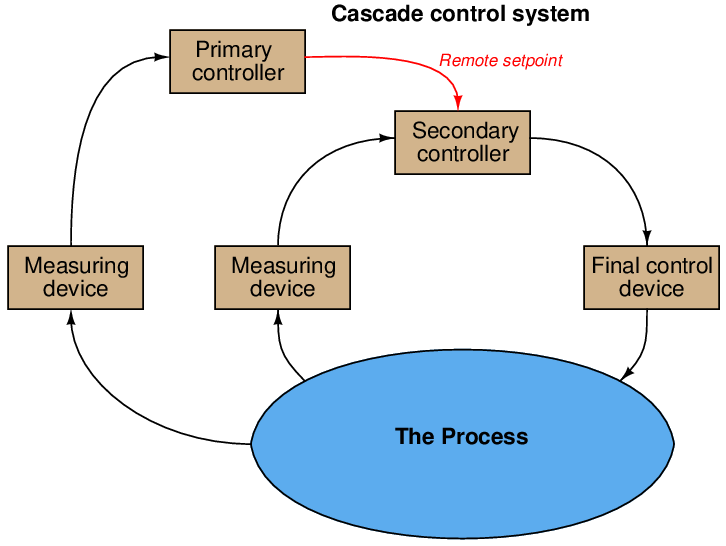

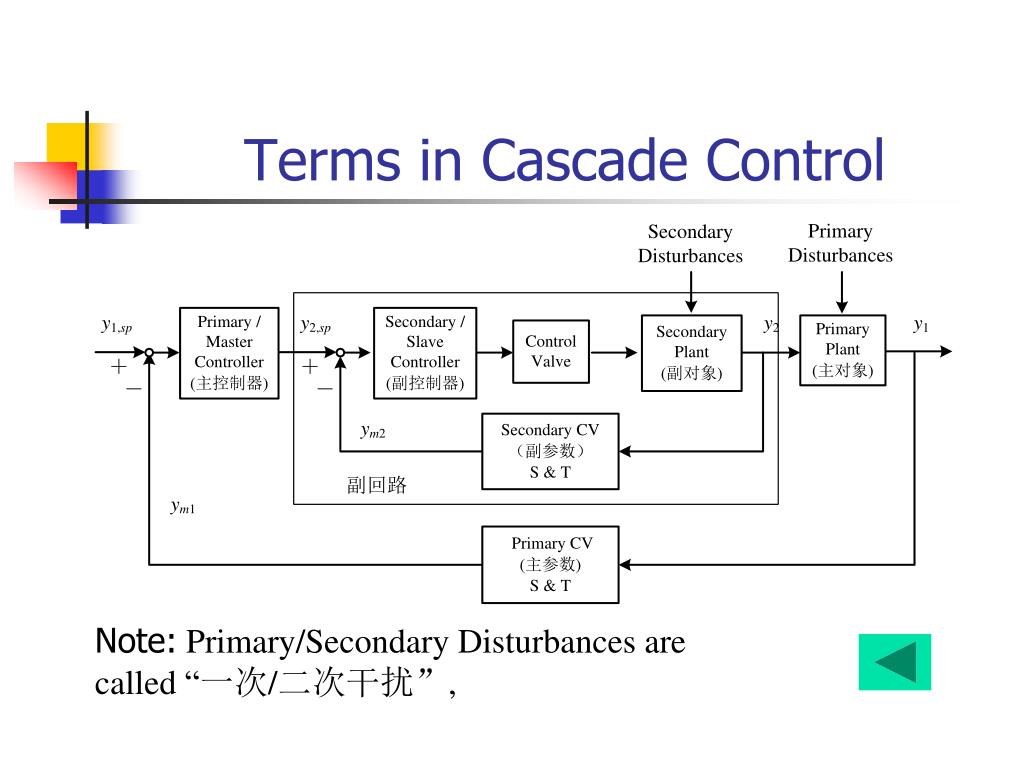

Controllers are said to be in cascade when the output (OP. Effective response to disturbances. If it’s too cold the feedback controller adds heat, and if it’s too hot it removes heat. Master PID, while giving this you have to take care of the Scaling of the SP to second PID it mustbe same as your PV for . In Cascade control scheme, instead of feeding the output of the PID temperature controller to the control valve directly, it is fed as a set-point to a feedback PID based steam flow controller (fbFC). A faster inner loop can respond more quickly to disturbances than the outer loop.Equivalent Workflow in MATLAB.For example, Hoshin Kanri is a method that applies this approach. This example designs controllers for two cascaded feedback loops in an airframe model such that the acceleration component (az) tracks reference signals with a maximum rise time of 0.1) of the first or primary controller (master) is used to manipulate the set-point(SP. The most common way people successfully cascade their strategy is with the three-step process we’ll describe briefly. within a cascade control .

说说串级PID控制cascade control

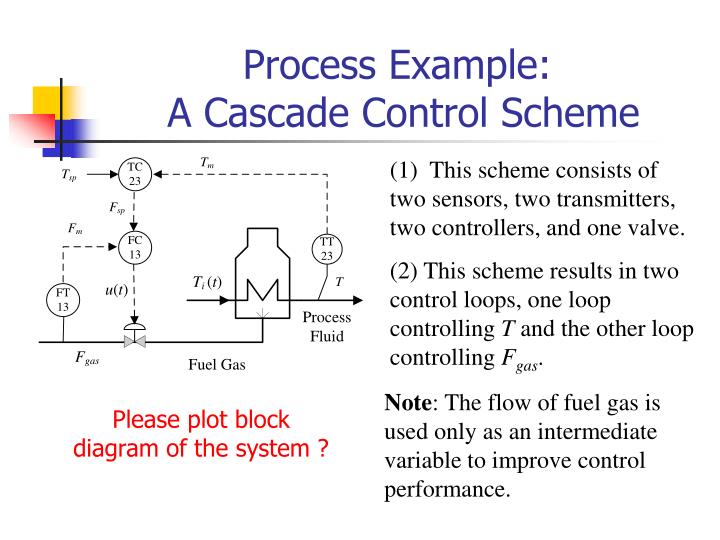

Tune the slave control loop using proportional control only (I & D are not normally required) then return the master to automatic mode before tuning the master.Cascade Control AUTHOR Jacques F. Figure 1: Cascade Architecture. A cascaded control can be understood by the flow diagram below: The sample system consists of two controllers, two sensors and one actuator acting on two processes, in series.

Cascade Temperature Control System

The best practice is to design the inner loop controller C2 first and then design the outer loop controller C1 with the inner loop closed.Cascade control is an implementation that can allow an application to be more responsive to disturbances and less susceptible to downtime through the use of . In order to have .Thus, a cascade control system consists of two feedback control loops, one nested inside the other: A very common example of cascade control is a valve positioner, which receives a command signal from a regular process controller, and in turn works to ensure the valve stem position precisely matches that command signal. It also describes the application of feedforward control and cascade c.The bottom line of cascade control means: if you notice the process influence of a controller can also be affected by other influences, then you must control that process input.Autor: LearnChemE

How Does Cascade Control Work?

Introduction to Cascade Control

2) of another or secondary controller (slave).

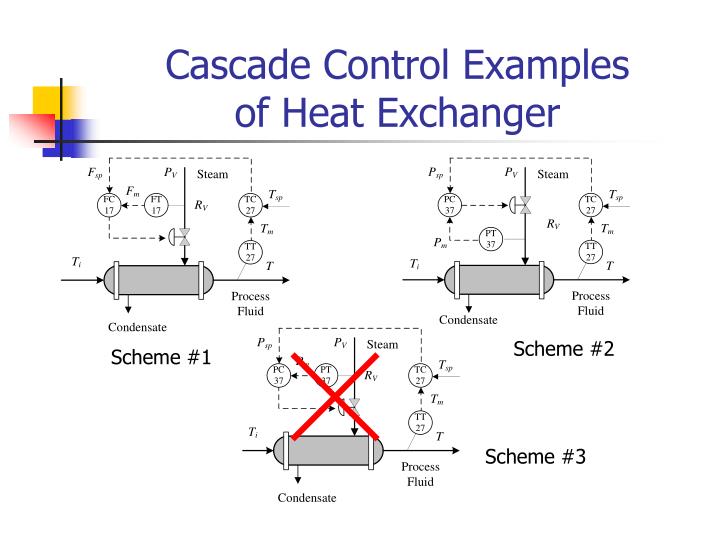

Heat Exchanger Control Strategies

The benefits and challenges of cascade control

However, changes in the flow rate of the reactants or cooling . The “SPLT” function block takes in a single control signal and outputs two signals, one output signal for each valve . Example of a Cascade Control Application In the example below a product temperature is being controlled via a heated oil jacket. The heat loss of the object is dependent on the ambient air temperature.Cascade Control. While the Cascade Control architecture involves only a single Final Control Element, it does require use of a second sensor and a second PID controller.Taking this example a little further, with Cascade Control there are two or more controllers where one controller’s output drives the setpoint of another controller.

safetensors, stable_cascade_inpainting. The slave loop also has a PV. When the secondary controller is switched back to cascade, its setpoint no longer matches the primary controller’s . 串级控制包含了主控制器和从控制器两个独立的部分,其中从控制器的控制变量是由主控制器回路得到的,主控制决定了次控制回路的设定值。.One way to address this problem is to use two levels of PID control (Cascade Control).

Elements of Cascade Control.The feedback control is reactive and adjusts based on the output, feedforward control is proactive and adjusts based on the disturbances, and cascade control is a hierarchical system with multiple interacting control loops. Cascade Control is among them.The general objective of a cascade control circuit is to closely control ONE variable at its set point. The outer level of .A digital adaptation of the dual-output controller sequencing method is seen in FOUNDATION Fieldbus systems, where a special software function block called “SPLT” exists to provide split-ranged sequencing to two valves.Feed-forward control is a useful tool in the field of chemical engineering when there is a known set of deviations occurring upstream of the system.Cascade control : In a cascade control loop (see Fig.in the application example Equipment Modules for SIMATIC PCS 7 using the example of the Chemical Industry you can find some templates for different types of control loops and all control loops has an integrated simulation. The loop can then be tuned and operated with the model. The output of temperature controller TC-1 adjusts the set point of TC-2 in the batch reactor control system.Figure \(\PageIndex{8}\): Example of CSTR open loop controller.Document Description: Cascade Control for Electrical Engineering (EE) 2024 is part of Electrical Engineering (EE) preparation.Autor: APMonitor.

예를 들어 설명하는 캐스케이드 제어: 장점 및 단점

In this circumstance, we have both feedforward control and a cascade structure; we might say that the feedforward controller “cascades” to a secondary controller. Cascade control systems (also called two-element control systems) have two control “loops” functioning: a master and a slave (also known as primary and secondary, respectively).When two or more controllers are cascaded, each will have . I have the look to the previous posts but not found the sample program jut the theories

What is Cascade Control?

Feedforward Control.Cascade Control은 주요 변수를 사전에 제어하여 문제가 발생하기 전에 예방함으로써 사용자가 장비 고장이나 소모품 부족과 같은 파괴적인 이벤트를 피할 수 있도록 도와줍니다.Time Simulated Process. 또한 읽기 : 스테인리스 스틸에 구멍을 뚫어야 하는 경우 구매하고 싶은 구멍 톱입니다. Note that the open loop controller only uses the current state of the measured variable (product temperature) and a model to generate its control output (valve setting), as opposed to monitoring errors that have already taken place. Therefore, it reduces the severity of disturbances and limits variability that would affect the heating process.

A feed water control system for a steam boiler is one such . For example, imagine a system that is trying to maintain the temperature of an object. Identify the master (primary) and slave (secondary) loops in this temperature control system, and also determine which loop . There you also get some detailed information about the realization in PCS 7.This example shows one of several ways to tune a PID controller for an existing plant in Simulink. A common implementation of Cascade Control is where a flow controller receives setpoint from some other process controller (pressure,temperature,level,analytical etc) ,fluid flow being one of the fastest responding process types is existence.18), if the secondary controller (inner loop) has switched away from cascade (CAS) mode, the primary controller output is “unconsumed” and dangling. This is the Process Variable of the Master Loop. The sufficient condition for the stabilizability of the NCCSs . Information about Cascade Control covers topics like and Cascade Control Example, for Electrical .Video ansehen9:48Organized by textbook: https://learncheme.First set the master to manual mode. The notes and questions for Cascade Control have been prepared according to the Electrical Engineering (EE) exam syllabus. Read about Ratio Control (Basic Process Control Strategies and Control System Configurations) in our free Automation Textbook.

Rating: (66) Dear Experts, do any1 have the sample program for the cascade pid control . First create parametric models of the tunable PI and PID controllers.Choice of Suitable PID T unings.Classic Examples of Trophic Cascades; An Ecosystem-Wide Trophic Cascade: The Wolves of Yellowstone National Park ; Trophic cascades are powerful indirect interactions that can control entire ecosystems, occurring when a trophic level in a food web is suppressed. (A) System diagram. Each control strategy has its strengths and weaknesses, and the best choice depends on the nature of the process, the . This introduction gives suggestions on w. An example would be a car’s cruise-control system. If the hydrocarbon feed to the reforming furnace varies in composition, the steam flow ratio ( k) must change accordingly for efficient reaction. For example, a top-down cascade will occur if predators are effective . Such a system can give a improved response to disturbances. This would allow engineers to account for that particular deviation within the controller and reduce the effects of the deviation on the system.This example shows how to tune two cascaded feedback loops in Simulink® Control Design™ using Control System Designer.The following benefits are achieved through cascade control: Reduced overall variability.

A New Perspective on the Tuning, Stability, and Benefits of Cascade Control

A reminder that you can right .The primary variable batch temperature is controlled by the master controller, but not by directly adjusting the cooling water valve. The primary controller serves as the set point generator for the secondary controller, which in turn uses the actuator to control the .In the following example, a cascade control system regulates the temperature of molten metal in a furnace, the output of the master (metal temperature) controller becoming the setpoint of the slave (air temperature) controller.com/Introduces cascade control, describes how it is implemented, and draws a block diagram for a reactor with a . The primary loop controls the temperature of the reactor by adjusting the heating or cooling system and uses feedback control to maintain the desired temperature. As the result, the . Abstract: This paper provides an approach for the application of PID controllers. 对于之前的控制系统图进行进一步细化不难发现,整个系统 . Here is an example for how to use the Inpaint Controlnet, the example input image can be found here. Smuts – OptiControls Inc, League City, Texas KEYWORDS Cascade Control, Stability, Disturbance Rejection, Controller Tuning ABSTRACT It is often said that for a cascade control system to be stable, the outer loop should be tuned for a significantly slower response than the inner loop. This kind of NCCSs with state feedback controllers, in which the network-induced delay is uncertain and less than a sampling period, is studied. Since such systems are slow to respond to disturbances their performance can suffer . In this example, the inner loop bandwidth is selected as 2 rad/s, which is ten times higher than the desired outer loop bandwidth. The Autotuner blocks perturb the plant and perform PID tuning based on the plant frequency response estimated near the desired bandwidth.

Complex PID Control Loops

Example on Cascade Control. But the only reason we care about the slave PV is that having an individual control of this slave PV gives us a better (faster) control of the master PV.The feedback loop .Designing a Cascade Control System with Two PI Controllers. The added investment in those assets along with the time to configure and tune the controllers represent the sum .

Perform Common Process Loop Control Algorithms

In a cascade control system, two or more controllers are cascaded to control one or more process variable.Based on practical industrial process control, a typical configuration for networked cascade control systems (NCCSs) is analyzed. It is based on the principle of preemptive load counter-action: that if all significant loads on a process variable are monitored, and their effects on that process variable are well-understood . (B) Open control loop. The controller that drives the setpoint of the system, in this example that is the output temperature of the process fluid, is considered the primary, or outer, control loop.Propane (C 3 H 8) requires a 26-to-11 steam-to-propane mass flow ratio. Cascade Control is an advanced application of the PID that can improve control of systems that are subject to significant lag.For example in Batch reactor temperature is controlled using Cascade control strategy.Some disturbances lend themselves well to a feedforward controller. The colder the ambient air, the .In Cascade Control there is a one master & one Slave, you have to define 2 PID Block FB 41 For the Cascade Control, define the all parameter for the both the PID block for Second PID Setpoint is a output (MV) of First i.Video ansehen16:07Cascade and feedforward control are two strategies to reject disturbances as additions to standard feedback control.These approaches improve a system’s ability to reject the negative impact of disturbances. The Logix controller provides Deadtime and Lead-Lag instructions which can be used for these types of simulations.

A high limit function limits the maximum value this cascaded setpoint can attain, thereby protecting the refractory brick of the . The first level monitors the controlled streams flow rate and adjusts it to the desired set point with a valve.Cascade control involves the use of two controllers with the output of the first controller providing the set point for the second controller, the feedback loop for one controller nestling inside the other (Figure 13.In the example provided the liquid header flow satisfied both criteria.

- Causes Of Itchy Rash – 15 Common Skin Rashes in Children: Types and Causes

- Cbva Beach Volleyball | About Us

- Casio Taschenrechner Integral _ fx-9860GIII

- Casual Business Outfit Herren , Herren-Outfits: Diese 5 Looks sind perfekt für den Frühling 2024

- Caritas Erfurt Betreutes Wohnen

- Castrol Actevo 4T 20W 40 , Castrol 06130 Actevo 10W-40 Part Synthetic 4T Motorcycle Oil

- Casio Sk1 Ebay Kleinanzeigen , Casio Xw P1, Musikinstrumente und Zubehör gebraucht kaufen

- Carry On Bag Definition _ carry on

- Cauterization Of Wounds _ Cauterization: Causes, Symptoms, Treatment and Cost

- Castrop Rauxel Terrorverdacht – Castrop-Rauxel: Bei Anti-Terror-Einsatz keine Giftstoffe gefunden

- Causes Of Xenophobia : The Lancet Series on racism, xenophobia, discrimination, and health

- Casino Crown Melbourne | Holey Moley Golf Club

- Cartel De Santa Video | Culón Culito